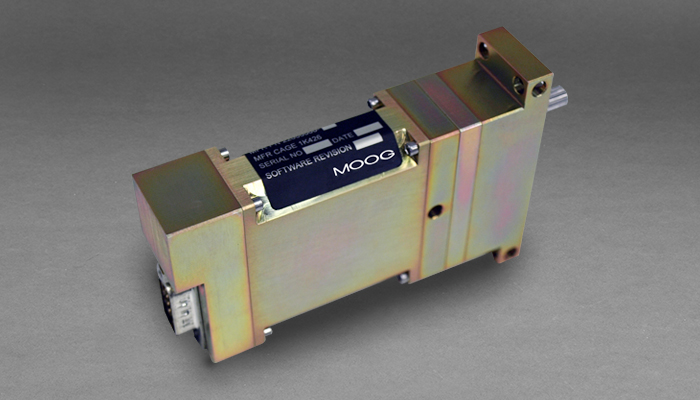

Rotary Actuators

Moog has been developing specialized high technology and utility electromechanical actuators for over 35 years. Our capability includes in-house design, manufacturing expertise, engineering support and qualification for these products.

Products range from 25 to 2,500 in-lb for rotary and 100 to 2,000 lbf for linear configurations. We can offer our assemblies with integral servo control electronics. Moog offers a variety of communication interfaces including analog, (+/- 10 VDC for example), RS232 / 422 / 485, R/C PWM and CAN Bus. We design for redundancy if required by our customer.

Moog is a FAA certified repair station and can offer hardware in support of repairs, upgrades or overhauls.

FAA / EASA Approved Repair Station Location, Blacksburg, VA

FAA Repair Station: 21MR057C

Cage Code: 99932

AS9100:2016 Certified

ISO9001:2005 Certified

1501 North Main Street

Blacksburg VA 24060-3127

USA Tel: +1-540-552-3011

Fax: +1-540-557-6719

These products were previously manufactured at Moog’s Springfield, PA, facility.

Models and Specifications

| Actuator Model | Size in (mm) | Load Torque in-lbs | Stroke degrees | Weight lbs | Operating Voltage vdc |

220* |

0.90 x 2.7 x 4.1 (22.9 x 68.6 x 104.1) |

50 or 100 Depending on Output Configuration | ±45 | 0.6 |

28 |

| 820* | 1.5 x 3.2 x 4.3 (38.1 x 81.3 x 114.1) |

80 Rated 150 Peak |

0 - 90 | 2.8 | 28 |

| 863* | 1.6 x 4.1 x 4.5 (40.6 x 103.9 x 113.0) |

150 Rated 320 Peak |

±45 | 2.0 | 28 |

| 935* | 2.3 x 4.8 x 6.6 (58.4 x 121.9 x 167.6) |

150 Rated 600 Peak |

±45 | 3.9 | 28 |

| 965* | 3.5 x 7.1 x 9.8 (88.9 x 180.3 x 248.9) |

2,200 Rated 2,500 Peak |

±90 | 11.5 | 28 |

*Servo actuator with integral electronics

Custom Designs and Specifications

Moog’s experience makes us familiar with numerous types of rotary electromechanical actuation requirements. We offer our customers a solution from dozens of product configurations or a baseline design. We recognize that it is not always possible to utilize an existing design, so we are equally comfortable in offering customization to meet individual customer needs. Customizations often include expanded angular deflection, unique mounting provisions and/or relocation of connectors or other mechanical parts. Moog works closely with each customer to help select the appropriate model with a focus towards meeting program milestones and goals.

Moog is committed to work with our customers in providing a solution to customer specific requirements if an existing design is not available. We are experts in design, development, qualification and certification. In addition to the hardware development, our sites include program management professionals who can support SDRL creation, milestone reporting and overall risk mitigation. Moog offers extensive engineering experience in mechanical, electrical and system disciplines to our customers.

| Actuator Model | Size (inches) | Load Torque (in-lbs) | Power Point | Stroke (degrees) | Weight (lbs) |

| 905-01 / 04* | 2.3 x 4.9 x 5.4 | 150 Rated 300 Peak |

Consult Factory | ±33 | 3 |

| 915* | 4.95 x 4.5 x 6.2 | 300 Peak | Consult Factory | ±46 | 7 |

| 971 | 3.0 x 3.48 x 6.56 | 15 Rated 200 Peak |

Consult Factory | ±30 | 3.2 Actuator Only |

*Servo actuator with integral electronics

Resources

Literature

Brochures

Infographics

3D Models

Actuator Product 3D Models

Related Industries / Markets / Applications

Helicopters

High-performance helicopter solutions meet the demands of rugged environments.

Armored Vehicles

Reliable power and data transfer in the most demanding batterfield conditions.

EO / IR Systems

Vast amounts of electrical and data signals transmitted across rotating axes.