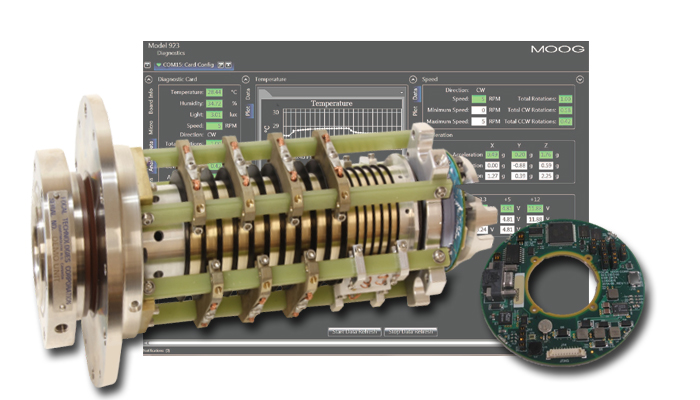

923-Slip Ring Sensor

Jump To:

Overview

Resources

Related Products

Features

- Real-time ESR health monitoring of temperature, relative humidity, shock, rotation and other parameters

- Programmable data logging intervals

- Hierarchical data logging with statistical summaries to optimize use of on-board memory

- Turns counting for monitoring slip ring rotations and life

- Small size and ruggedized electronics to mount inside an ESR

- Diagnostic GUI software available for Windows-based PC

- Open diagnostic protocol for customer development

- On-board real-time clock (RTC) with battery backup

- Sensor bus port for future expansion

- Used with high voltage units up to 7.2 KV

- Pressure tolerant up to 6000 psi

Benefits

- Tracks ESR health for better planning of maintenance intervals

- Allows early identification of potential problems in a rotary joint, e.g. increasing temperature

- Provides remote access to diagnostics for technical support

- Establishes baseline and historical data for ESR monitoring

- Provides a “black box” record of events leading up to a fault condition

Typical Applications

- Real-time ESR health monitoring

- Maintenance planning for ESRs

- Black box storage for fault analysis

- Shock monitoring

- Data collection for: ESR/EOSR units, hydraulic utility swivels, electrical swivels and FPSOs

- Marine applications: surface (dry) and pressure tolerant (wet) slip rings, hazardous an non-hazardous area

Resources

Literature

Data Sheets

User Manuals

Technical Support

Telephone: +1-902-468-2263