Custom Multiplexers

Technical Innovation

We are a leading supplier of COTS and custom fiber-optic telemetry systems with over 2000 fielded systems around the world. We pioneered features like embedded diagnostics and automated fiber switching for redundancy. Our “busless” backplane architecture provides the lowest possible video and data latency, since the added delay of buffers and bus addressing are avoided. Furthermore, with modular designs at the card and daughter-card level, systems are easily expanded and reconfigured. High reliability in harsh environments is ensured through extensive analysis, thorough design verification, qualification, and product stress screening.

We emphasize miniaturization and design flexibility through the use of Field Programmable Gate Arrays (FPGAs). Advanced CAD systems and an extensive library of proven designs enable rapid development of new products or repackaging of existing solutions. We now offer a full range of multiplexer products, from single channel media converters for Ethernet and HD-SDI to multi-channel CWDM and DWDM systems supporting 16 or more video lines, 128 serial data channels, multiple digital I/O, plus 10/100/1000M Ethernet and high bandwidth sonar interfaces, all on a single optical fiber.

Multiplexing systems can be based on a symmetric topology, where signal formats are the same at each end, or on an asymmetric topology, where various signal formats at one end are converted to a common, integrated digital format at the other end. Asymmetric multiplexers often use a standard format, such as VME or Gigabit Ethernet, for integration with data acquisition and control systems.

Previous custom designs include a number of high reliability systems with MTBFs over 200,000 hours, data acquisition systems with 256 sensors, and long-haul systems that operate on 200 km fiber links. The high data capacity of optical fiber inherently builds in “future proofing” of designs for increasing the number of channels or data rates supported.

- Ruggedized design for harsh environments (wide temperature range, high shock/vibration)

- Very low latency, modular design, and compact size

- Support for video (analog and digital), serial data, Ethernet, and other signal formats

- Up to 10 Gbps per wavelength using FPGA-based Time Division Multiplexing (TDM)

- Up to 16 wavelengths per fiber using Coarse Wavelength Division Multiplexing (CWDM)

- Advanced diagnostics and health monitoring

High Reliability for Harsh Environments

High reliability of custom products is implemented at all design and production stages in an ISO-9001 environment. Reliability analysis is supported by field experience and Relex software, allowing use of predictive models, such as 217Plus, PRISM, Telcordia, and FIDES, as well as failure mode analysis. Card level options include conductive cooling, board stiffeners for improved vibration tolerance, hot swap capability, and signal redundancy. At the system level, our custom designs include redundant optical transceivers, auxiliary power supplies, and robust transmission protocols that reduce the probability of accepting corrupted data (residual errors) to extremely low levels. The various options are applied as appropriate for the given cost, reliability, and environmental requirements of the system over the intended product life cycle.

Several processes are used to further support high reliability designs. Besides the acceptance testing at rated temperatures used for all electronic products, high-reliability products receive additional environmental stress screening and qualification testing to further validate product reliability and life. Detailed analyses are conducted, including the calculation of product reliability and life, supported by manufacturer’s data, empirical data, and component traceability. Additional testing includes shock, sinusoidal vibration, random vibration, humidity, acceleration, low pressure (altitude), and high pressure (in oil). Our engineering department will work closely with you to develop test plans for design, production, and qualification that make sense for your application.

Multiplexer products include advanced diagnostics and health monitoring functions to ensure systems are operating properly and to provide early warnings of any negative trends, for example degradation of cabling. Critical performance parameters, such as optical power, rail voltages, temperature, and fault conditions, are available through serial channels or Ethernet protocols. Customer equipment may access the diagnostics directly through open protocols, e.g. Modbus, or via Graphical User Interface (GUI) software. Built-in test features, such as bit error rate tests and video test patterns, simplify system-level troubleshooting by helping to isolate any connection problems.

We provide rapid solutions for multiplexing and data conversion applications in the harshest environments, designed to your specifications. The results are proven, rugged products.

Typical Applications

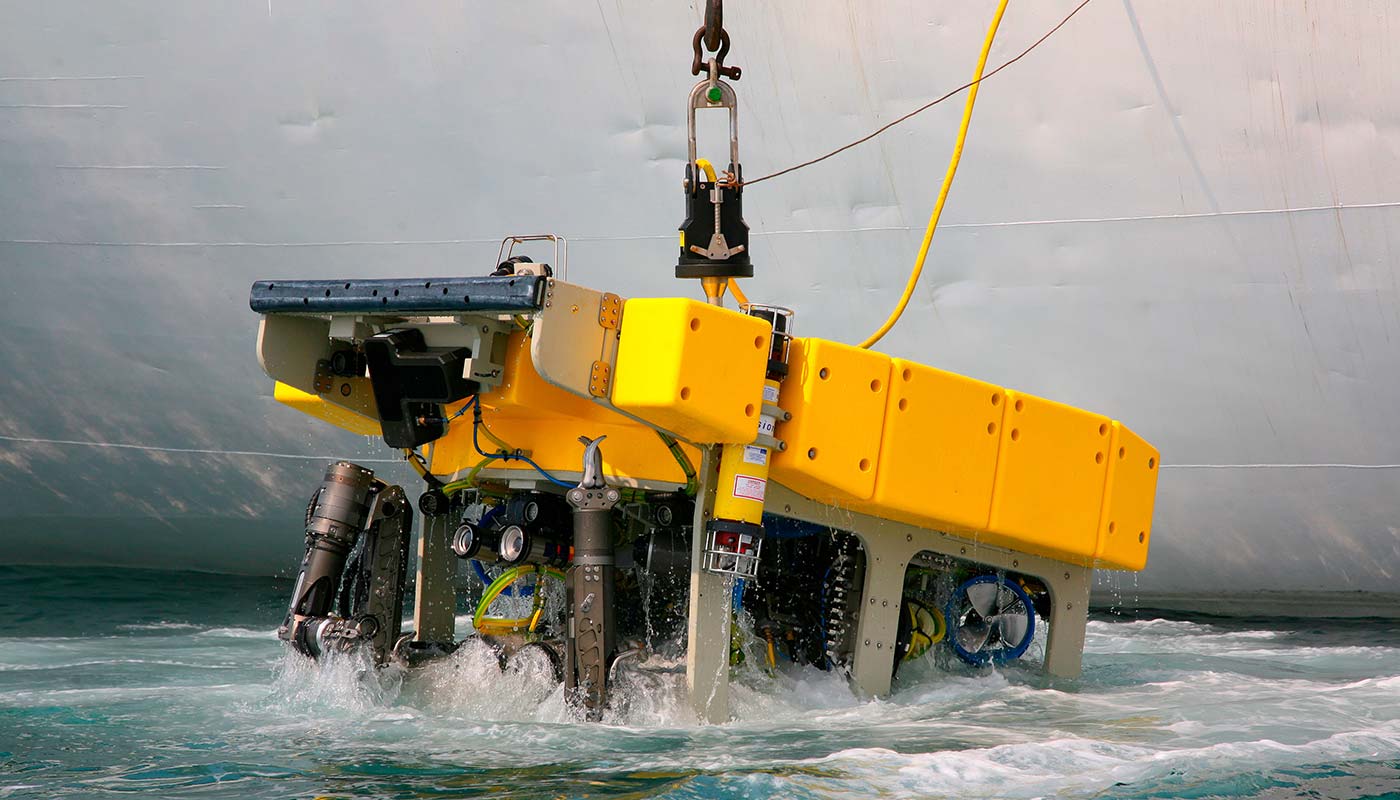

- OEM configurations for Remotely Operated Vehicles (ROVs)

- Subsea control modems for SEMs and flow meters

- Remote data acquisition systems for use in harsh environments

- Fiber video/data networks for turreted vehicles

- Fiber extenders for radar and sensor applications

- Multi-gigabit digital video links for electro-optic (EO) pods for surveillance and targeting

- Data links for motion simulators and other rotating test beds

- Integrated solutions with Focal’s Fiber Optic Rotary Joints (FORJs)

for Gigabit data transmission through rotating interfaces

Resources

Technical Support

Telephone: +1-902-468-2263