Get In Touch

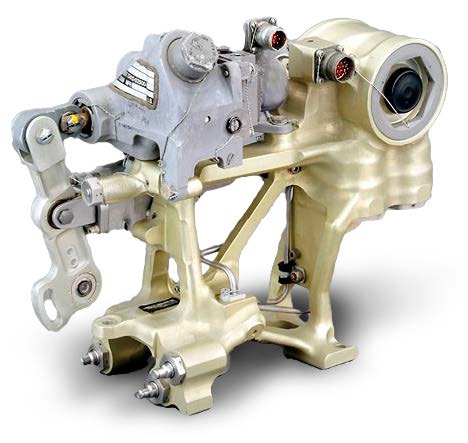

Modifications and Upgrades - Blackhawk Pitch Trim Servoactuator for US Army AMCOM, Redstone Arsenal

Challenge:

Due to operation in desert environments, piston surface and scraper rings were experiencing premature wear. Frame feet were corroding due to pooling of moisture, which increased depot maintenance costs. Actuators were being removed from aircraft due to appearance of out-of-spec leakage, causing artificially low mean time between unscheduled removals (MTBUR).

Solution:

To improve MTBUR and reduce depot maintenance costs, Moog redesigned three key parts:

1. Piston and scraper ring configuration for improved life in desert environment

a. New HVOF-applied tungsten carbide piston coating used, which is 50% harder than chrome

b. New scraper rings were developed for increased wear resistance and scraping efficiency

2. Frame feet to enable the surface to shed moisture

3. End cap and crank shaft to re-route leakage to a larger internal cavity

Customer Benefit:

By eliminating the cause of nuisance removals, MTBUR increased by an estimated 35-40%. Reducing piston rework, repair and seal replacement, as well as frame repair and replacement significantly reduced depot maintenance costs.

Case Studies

Non-OEM Repair and Overhaul Services