Wind turbines require reliable transmission of power and data signals from the nacelle to the control system for the rotary blades. Moog’s slip rings provide the performance and quality needed in demanding environments. Costly downtime is eliminated by using fiber brushes and robust mechanical components in the slip ring design.

For more information about how wind turbine slip rings can be tailored to fit your specific application, contact our applications engineers.

Moog Slip Ring Advantages

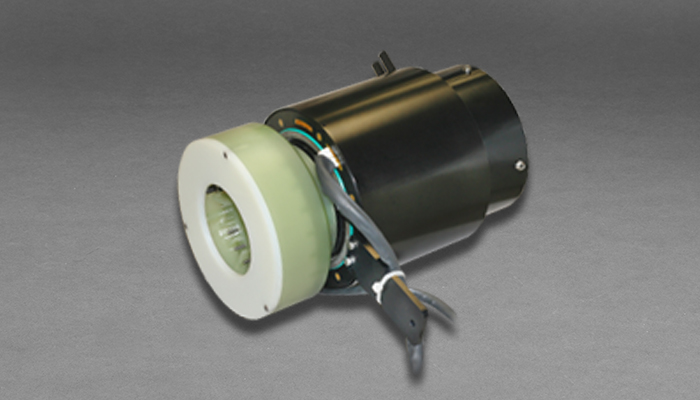

Moog offers a WP7129 direct replacement pitch control slip ring for the NEG Micon NM72 / 82 wind turbines. Moog’s unit mounts directly to the gearbox with a through passage for the hydraulic lines and wiring.

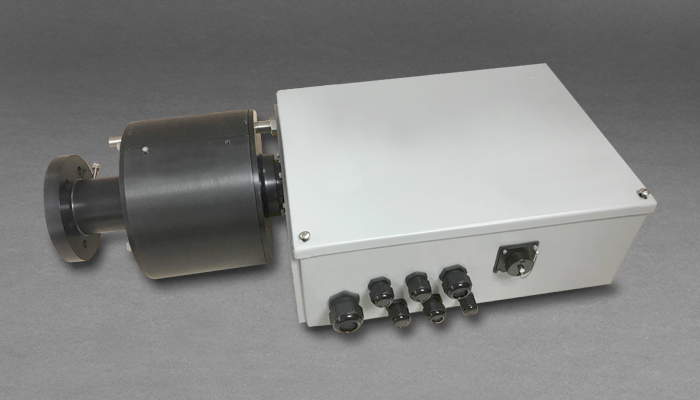

Moog offers a WP7286 direct replacement pitch control slip ring for the GE wind turbines. The design bolts to the existing gear box and provides numbered terminal blocks to match the turbine wiring harness.

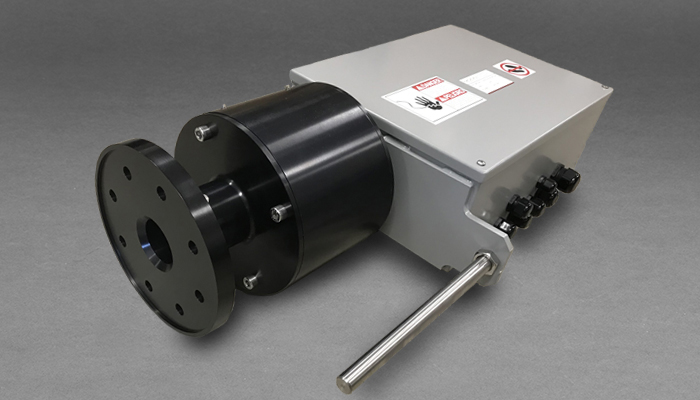

Moog offers a WP7358 direct replacement pitch control slip ring for the Suzlon S88 wind turbine. Moog’s unit provides direct connection to the gearbox with wire terminal connections in both the stator and rotor junction boxes. Each unit is shipped with a heater already installed for cold weather installations.

Moog offers the superior fiber brush technology that has an extensive lifetime of over 100 million revolutions. This technology does not require lubricants and is characterized by low wear generation for minimal maintenance. Also the temperature range and the packaging of this product matches the harsh conditions required by this industry.

Our engineering department is available for consultation to help you tailor a solution to meet your requirements.

Moog provides reliable solutions for wind turbines in cold climate or climate change regions. We offer slip rings for blade heating - with both anti-icing and de-icing capabilities. Our products can be retrofi t onto the most established wind turbine models, for both hydraulic and electric blade pitch control.

Moog's anti-icing / de-icing and aftermarket solutions as presented at O&M and Safety Conference 2023.

Watch members of Moog's wind team, Steve Black, Fabian Goeden and Adan Cabrera, display Moog's latest offerings including our newest wind turbine slip ring solutions from Moog Rekofa and condition monitoring for slip rings, at AWEA 2019.