Screws

Ball Screws

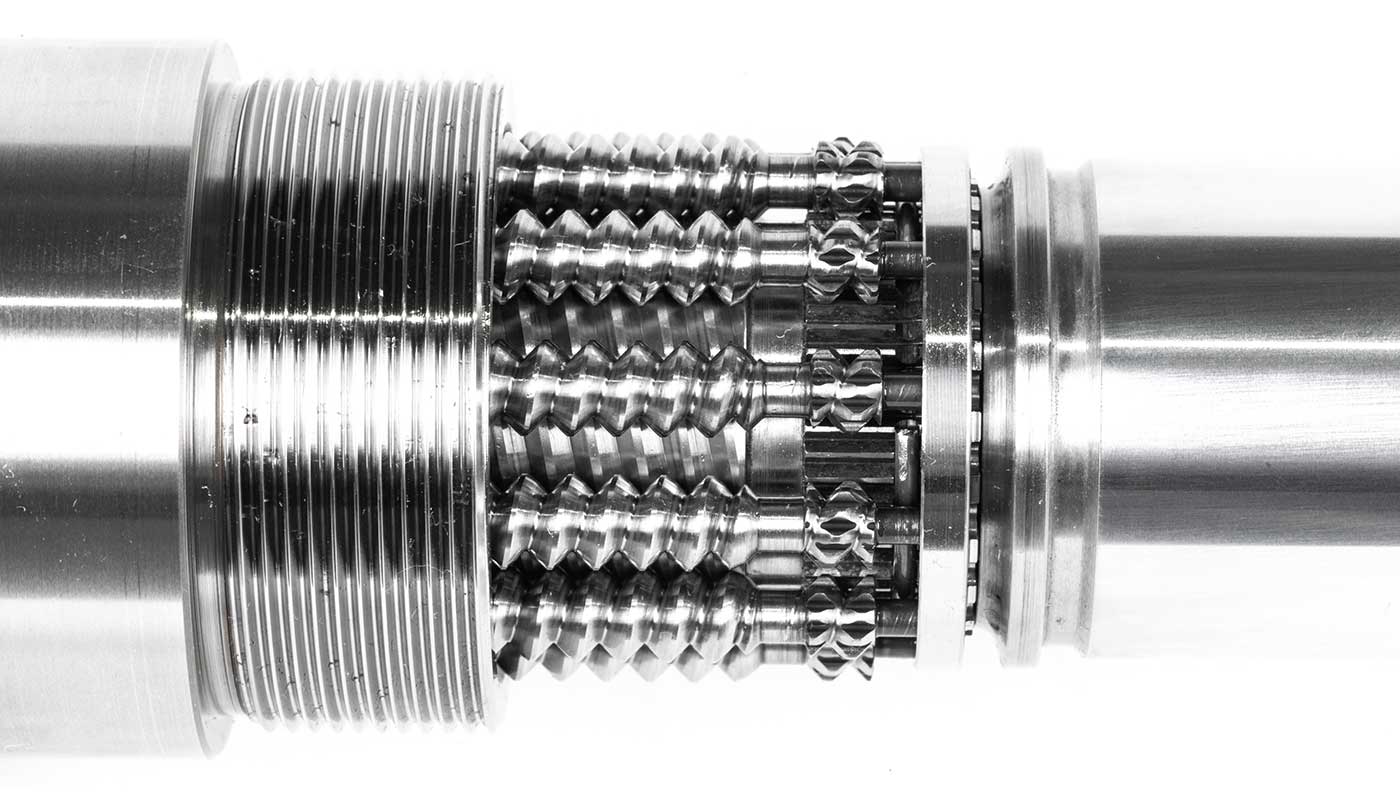

Planetary Roller Screws

Inverted Roller Screws

Customized Designs

Moog is the ideal partner for co-designing the perfect screw for each machine. Our extensive customization capabilities and design expertise allow us to adapt our screws to existing machine layouts, as well as facilitating a greater configuration freedom for brand new projects.

Resources

Literature

Catalog

Data Sheet

News Release

Discover how Moog Roller Screws helped BMB S.p.A improve its production performance.