The Moog Total Solution and the New Electrohydrostatic Actuation System the Highlights at SPS IPC Drives Italy 2018

18 May 2018

Milan, Italy, Moog will present its ‘Total Solution’ at stand B029 Hall 5 at SPS IPC Drives Italy 2018. Moog’s Total Solution offers electric, hydraulic and hybrid technologies, using a ‘technology neutral’ approach whereby the company helps machine builders to use technology that will help them achieve all performance goals. By taking this ‘total’ approach, Moog helps customers achieve optimum solutions that meet the specific needs of customers across multiple applications.

The SPS event provides a unique opportunity for the automation sector to experience Moog's solutions, and to discover the newest technologies it has to offer. Some highlights are the Electrohydrostatic Actuation System (EAS) demonstration, showing an application co-designed with the American vehicle components manufacturer Meritor, and the Large Motor Solution (LMS) system that provides innovative, integrated, primary motion control for Servo Presses.

The Electrohydrostatic Pump Unit (EPU) is a next-generation hybrid system designed to combine the advantages of both electro-hydraulic and electro-mechanical technologies. It brings together the reduced consumption of an electrical system and the power of a highly reliable hydraulic system with easy energy storage for failsafe motion. The unit is available either as a single product, or as an integrated system called the Electrohydrostatic Actuation System that combines the EPU with additional components the customer requires.

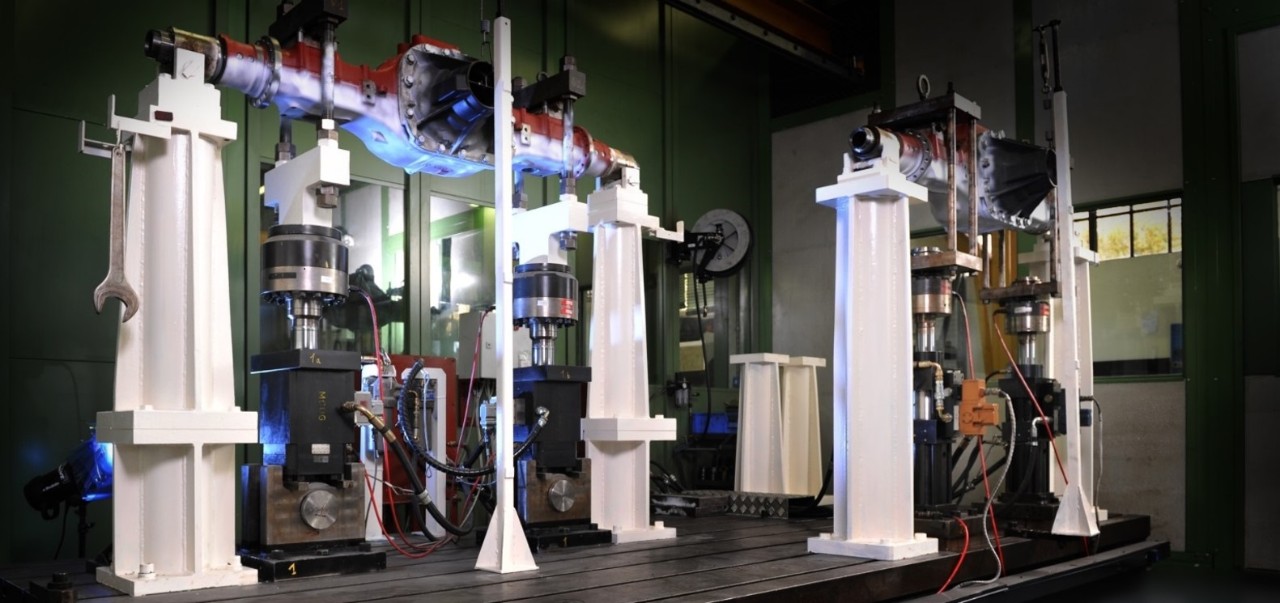

The axle fatigue test system, designed for Meritor – an American multinational, global supplier of integrated systems, modules and components such as axles, suspensions and braking systems for the transport and industrial sectors – and tested at its Cameri laboratory in Novara, is an example of a successful application using the EAS technology. Bruno Fazzari, Sales Director, Moog Italiana, and Arnaldo Stalla, Meritor’s Testing and Prototype Senior Manager will present, the benefits of using this decentralized, stand-alone system to provide greater energy savings and lower costs, reduced envelope space and higher performance, in a presentation on May 23 at 2.00 pm in the Lampone Room, Pavilion 7.

“One of the major advantages of the EPU is its capacity to implement a decentralized transmission system that eliminates the need for hydraulic power units and complex piping, flexible pipes and filtration systems, reducing the need for additional space on each test system,” notes Moog’s Bruno Fazzari. He adds that, “this proved to be the most interesting aspect for Meritor, because it made it possible for us completely to eliminate pipes and external high-pressure hydraulic supply systems. In fact, the servo-actuator is connected to the control system exclusively through an electrical cable, and two signal cables for the force and position transducers.”

Arnaldo Stalla, Testing and Prototype Senior Manager for Meritor, adds, “The market in which we operate is subject to strict European legislation, which requires that all components including axles pass very strict testing. These must undergo fatigue tests, which simulate both vehicle life cycle and overall efficiency. Given the dimensions of the test systems themselves, the costs involved in carrying oil through pressure lines for distances of over 40 m are quite high. Therefore, as a result of our collaboration with Moog, and by choosing to use the EPU, we have succeeded in solving these critical issues, while also increasing performance, reducing implementation and operating costs and cutting energy consumption.”

Moog's hybrid technology makes it possible to achieve the same levels of functionality and performance one would expect from an electro-hydraulic cylinder, with the benefits of control by an electromechanical actuator.

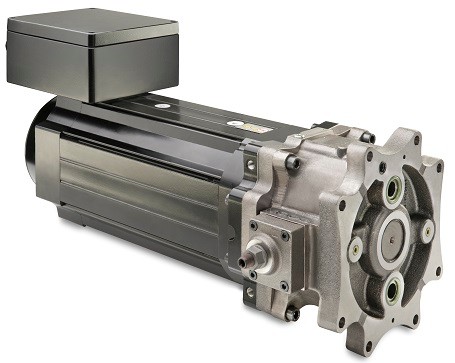

One innovation featured in the Moog booth is the new Large Motor Solution (LMS), Moog’s response to the demand for advanced electric servo systems for next-generation machines. The LMS is an integrated primary motion control system, comprised of high-power Servo Motors, Servo Motor Actuators, control gear, energy management equipment, feeding mechanisms and motor control software. This innovative solution provides numerous options for customizing products and systems, and ensures the highest levels of performance for equipment such as Servo Presses in terms of power and dynamics.

Moog's Large Motor Solution offers Moog's highly reliable hardware components, a system architecture with a scale of 139 kW to 1 MW and the capacity to achieve elevated power and torque values. The LMS is, ideal for applications such as Servo Presses for the automotive and industrial sectors, drilling platforms, industrial installations, and oil, and gas exploration and production.