Radial Piston Pump with Digital Control

Jump To:

Overview

Specifications

Resources

Overview

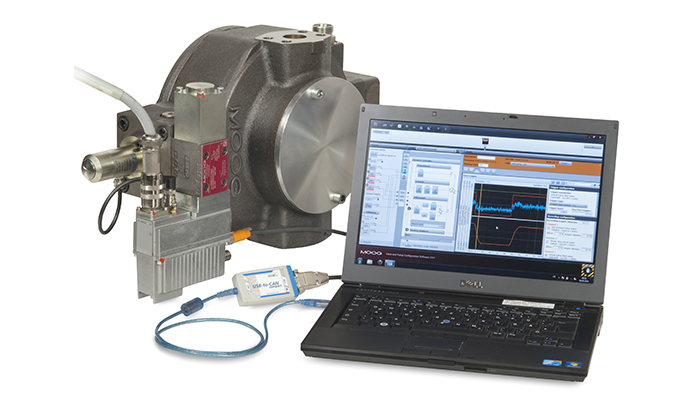

The robust and contamination-resistant design of the RKP Pump is well-established in the market. It is now enhanced with a new Servo- Proportional Pilot Valve with digital on-board electronics for flow and pressure regulation, tuning and diagnostics. The high-performance, flexible microprocessor control system design makes this pump the ideal solution for a variety of pressure and flow-controlled systems.

- Closed-Loop Control: The new pilot valve with digital onboard-electronics provides more dynamics and improved precision control of the basic pump functions (flow and pressure regulations).

- Analog or Digital Control: The ability to function as a CANopen device or as a traditional analog device ensures compatibility with several PLC structures.

- On-the-Fly Adjustment: Changing the parameters of the pressure controller "on-the-fly" enables optimization of the performance of sequential machine processes with multiple cylinders, a process nearly impossible with traditional pump operations.

- Optimized Multiple Pumps: Optimized multiple pump arrangements in master-slave format now allows users to easily combine multiple servo-pump stages in one common oil volume, while providing superior pressure control.

- Advanced Troubleshooting: Full access to all internal parameters during runtime helps to minimize downtime and enables users to diagnose common faults via Human Machine Interface (HMI) or laptop interface.

- Save Space and Assembly Time: No assembly space inside the cabinet is required due to the design of the Digital Control Pump including onboard-electronics.

Specifications

| Specifications | |

Displacement (cm3/rev) |

19, 32, 45, 63, 80, 140, 250 |

Type of construction |

Pump for open circuit with various control devices |

Weight [kg (lb)] |

22 (49) to 236 (521) |

| Inertia [kg/cm2 (lb/in2)] | 17.7 (6.0) to 1555.0 (531.4) |

| Ambient temperature range [°C (°F)] | -15 to +60 (+5 to +140) |

| Maximum speed [min-1] at inlet pressure 1 bar (14.5 psi) abs. | 1,850 to 2,900 |

| Maximum operating pressure [bar (psi)] medium pressure series (RKP 19, 32, 45, 63, 80 and 140) | 280 (4,000) |

| Maximum operating pressure [bar (psi)] for high pressure series (RKP 19, 32, 63, 80, 140, 250) | 350 (5,000) |