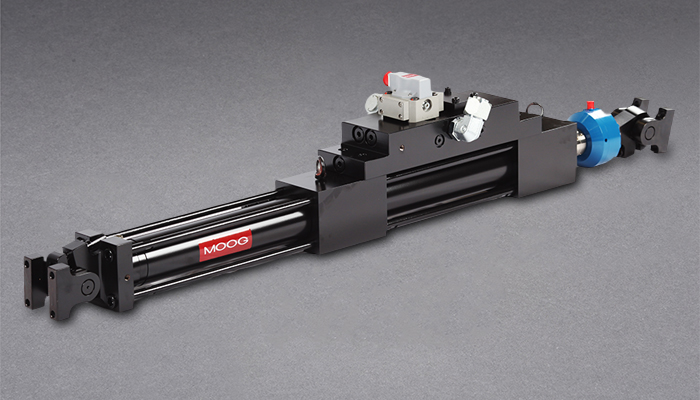

Hydraulic Double-Ended Test Servo Actuators

Overview

RELIABLE MOOG FATIGUE RATED ACTUATORS ARE THE TRUSTED BRAND FOR HIGH PERFORMANCE TEST SYSTEMS

For years, test engineers have been looking for actuators that deliver dependability, less maintenance and high performance, yet are available at an affordable price. Their goal has been to expedite tests to obtain accurate test results more efficiently. With deep roots in electro-hydraulic servo control expertise and global test experience, Moog has designed servo actuators for some of the world’s most demanding applications.

From Primary Flight Control System Actuators to Automatic Gap Control Actuators used in a steel mill product lines, the hybrid polymer bearings allow for high side-load capacity with increased durability.

- Standard options include 8 force options from 15 kN to 1000 kN and 4 stroke lengths from 100mm to 500mm

- Extensive options available to meet any application need

- High-performance operation delivers dependability through less maintenance and limited downtime

- Can be used as a "building block" component for customized configurations

ADVANCED SOLUTIONS BUILT FOR A VARIETY OF INDUSTRIAL APPLICATIONS

No matter how demanding your application, Moog Engineers have developed these maximum performance electrohydraulic actuators for long-life durability and predictable results.

- Automotive Durability Testing

- Rolling Stock Structural Testing

- Aeospace Fatigue Testing

- Covin Engineering Structural Testing

- Package Vibration Testing

Specifications

| Model Number | Rated Force kN (kip) |

Working Stroke mm (in) |

Cushion Length/End mm (in) |

Rod Diameter mm (in) |

Bore Diameter mm (in) |

Piston Area sq cm (sq in) |

|---|---|---|---|---|---|---|

| C086A73 | 15 (3.3) |

100, 150, 250 (4, 6, 10) | 20 (0.79) |

45 (1.8) |

57 (2.2) |

9.6 (1.5) |

| C086A74 |

25 (5.5) |

100, 150, 250 (4, 6, 10) | 20 (0.79) |

45 (1.8) |

63 (2.5) |

15.3 (2.37) |

| C086A75 |

50 (11) |

100, 150, 250, 500 (4, 6, 10, 20) | 20 (0.79) |

80 (3.1) |

100 (3.9) |

28.3 (4.39) |

| C086A76 |

100 (22) |

100, 150, 250, 500 (4, 6, 10, 20) | 20 (0.79) |

80 (3.1) |

120 (4.7) |

62.8 (9.74) |

| C086A77 |

150 (33) |

100, 150, 250, 500 (4, 6, 10, 20) | 20 (0.79) |

80 (3.1) |

130 (5.1) |

82.4 (12.8) |

| C086A79 |

250 (55) |

100, 150, 250, 500 (4, 6, 10, 20) | 20 (0.79) |

100 (3.9) |

165 (6.5) |

135 (20.9) |

| C086A7A |

500 (110) |

100, 150, 250, 500 (4, 6, 10, 20) | 12 (0.47) |

140 (5.5) |

240 (9.4) |

298 (46.2) |

| C086A7B |

1000 (220) |

100, 150, 250, 500 (4, 6, 10, 20) | 12 (0.47) |

160 (6.3) |

300 (11.8) |

506 (78.4) |