Naval Defense Solutions

Delivering high-precision motion control and electronic solutions to many of the world’s naval forces

Moog’s naval defense solutions deliver precision, reliability, and control in the most demanding maritime environments. From advanced motion control systems for shipboard weaponry to rugged actuation technologies for sonar, radar, and stabilization platforms, our innovations ensure mission readiness across surface and subsurface fleets. With decades of experience supporting naval operations worldwide, Moog empowers maritime forces with the agility and performance needed to dominate in dynamic, high-stakes conditions.

Defense Products for Naval Systems

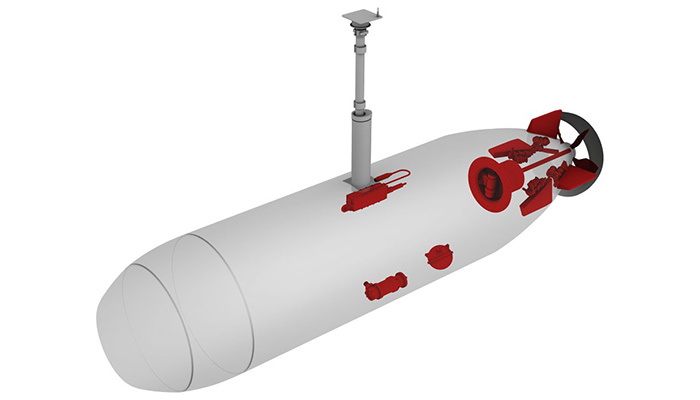

Unmanned Underwater Vehicles (UUVs)

For ROV and UUV platforms, Moog provides motors, controllers, actuators, servo valves, and other equipment. We are making investments in future technologies to support UUVs. Our solutions support steering, diving and propulsion systems as well as other undersea functions for both military and industry. Moog facilities in the United States, Canada, Germany, and Australia are dedicated to subsea technologies serving the naval and marine industries.

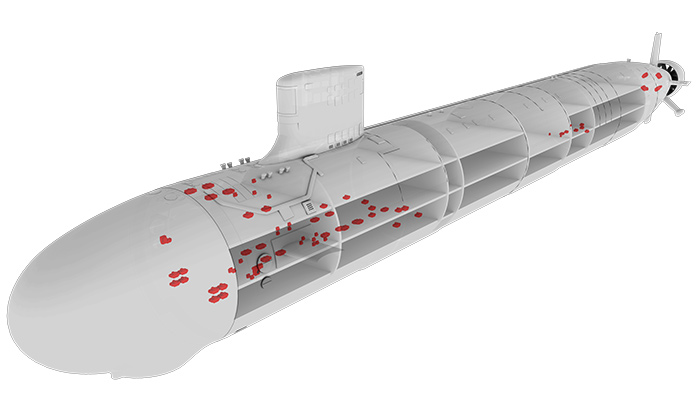

Submarine Actuation

Moog’s legacy supplying actuation in U.S. Navy submarines extends more than 50 years, from the George Washington-class all the way to today’s Virginia-class and the future Columbia-class. Our critical control systems operate valves, open lock hatches and provide propulsion from the torpedo room to the engine room and everywhere in between.

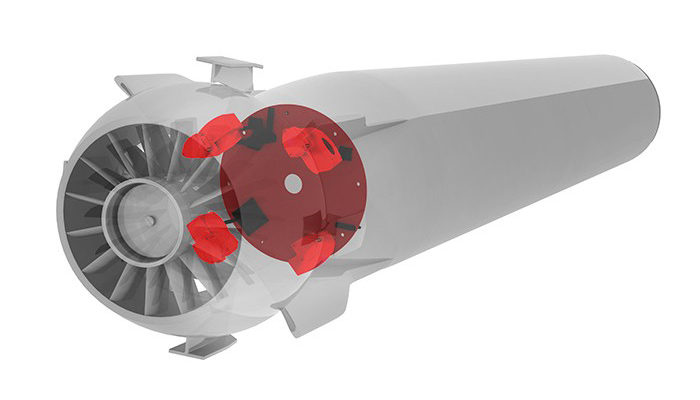

Torpedo Steering Systems

Moog supplies the tail cone for the Mark 48 torpedo. Our servoactuator fin system controls technology enables precision steering to guide Mark 48 torpedoes to intended targets. Moog is also supports torpedo electrification upgrades for propulsion and fin control systems.

Surface Ship Actuation and Weapons

Moog’s legacy supplying actuation in U.S. Navy submarines extends more than 50 years back to the USS George Washington class all the way to today’s USS Virginia class and the future Ohio-class replacement

Moog actuation is also found in mission critical surface ship applications such as the propulsion plants of both USS Nimitz and USS Gerald R Ford class aircraft carriers.

Featured Videos

A Dedicated SUBSAFE Facility

Moog’s 90,000 sqft Orrville Operations designs and manufactures precision hydraulic, pneumatic and electromechanical actuator assemblies to support the U.S. Navy including SUBSAFE Design Review (SSDR) rated and Level 1 components. The facility is strategically positioned to support our customers’ needs from engineering design and development, manufacturing, NDT, to final assembly and testing of our motion control solutions that serve the U.S Navy.

Our motion control solutions have been in service for decades across many platforms complying with stringent qualification requirements such as shock, vibration, acoustic criteria, endurance and seawater corrosion resistance.

We offer sustainment for the fleet through Moog’s Sustainment Services for original equipment, build to print manufacture as well as design and development services.

- Decades of experience meeting stringent naval specific quality standards including SSDR, Level 1 and MIL-I-45208.

- Structureborne vibration test capability per MIL-STD-740-2.

- Exceptional Machining capability and repeatability.

- Commitment to Quality ISO9001:2015 Certified

- Reliable On-Time Delivery

Read More About What We Offer

Click the file icons below to view the literature in a separate tab.

Featured News

The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.