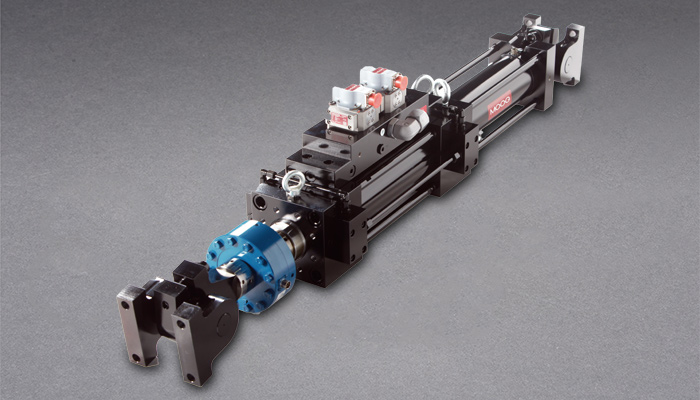

Hydrostatic Endcap Test Actuator

Jump To:

Overview

Specifications

Resources

Overview

Optimization design balance between top performance and cost effectiveness

Moog brings decades of expertise in high-performance actuators for demanding test environments. The Moog Hydrostatic Endcap Servo Actuator is engineered for complex test applications like automotive component testing, multi-axis platforms, and vibration simulation.

- Features a symmetric cylinder with a hydrostatic bearing is embedded in the endcap

- Design of 4 hydrostatic pad enables low friction, minimal stiction and high dynamic response

- It combines structural innovation and material optimization to raise overall test performance

Modular configuration options are available to meet your exact application needs

Integrated manifold and modular configurations provides flexibility to tailor the products to diverse test scenarios. Overall design helps you to reduce the system adaptation time and deliver a high-performance, cost-effective solution for you.

- Integrated manifold simplifies piping and improves system integration efficiency

- Optimized flow path enhances flow uniformity and accelerates response time

- Tungsten carbide coating on the piston rod for enhanced stability and extended service life

- Dual-end cushion absorb end-of-stroke impacts to protect both actuator and test specimen

Specifications

| Model Number | Rated Force kN |

Working Stroke | Cushion Length / End mm |

Rod Diameter mm |

Bore Diameter mm |

Effective Piston Area square cm |

|---|---|---|---|---|---|---|

| C086-6E2 | 15 | 100, 150, 250 | 27 | 45 | 57 | 9.6 |

| C086-6E4 | 25 | 100, 150, 250 | 27 | 45 | 63 | 15.3 |

| C086-6E5 | 50 | 100, 150, 250 | 27 | 80 | 100 | 28.3 |

| C086-6E6 | 100 | 100, 150, 250 | 27 | 100 | 130 | 54.2 |

| C086-6E7 | 150 | 100, 150, 250 | 27 | 100 | 140 | 75.4 |