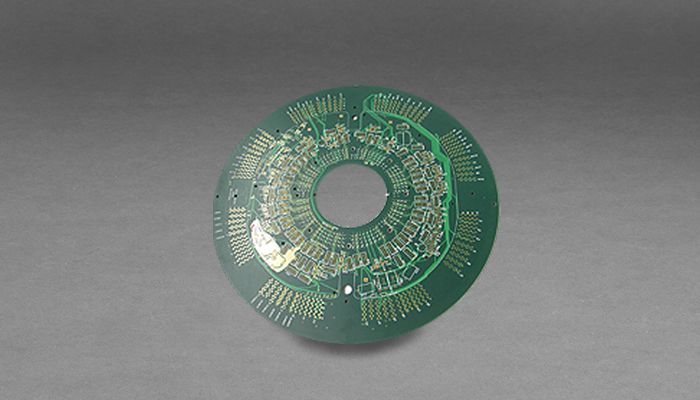

Custom Circuit Boards

FEATURES

- Micro-section lab with fully trained lab technicians

- OEM enclosed vacuum press with recipe generation

- Laser ablation, skiving, and routing technology through the use of Excellon Cobra V1000 UV / CO2® Laser

- Polar instruments, impedance calculators and equipment, and circuit resistance / insulation resistance testing

TYPICAL APPLICATIONS

- Military Aircraft

- Military Ground Vehicles

- Missile Guidance

- Medical Products

- RF Microwave / Antennas

- Wind Turbine

- Cell Towers

- Satellites

Manufacturing Capabilities

| Description | Standard | Review |

| Layer Count | 16 | 24 |

| Board Thickness | .004-.125 in | Up to .450 in |

| Copper Foil Thickness (Minimum) | .5 oz./ft² | .25 oz./ft² |

| Copper Foil Thickness (Maximum) External / Internal Layer | 2 oz./ft² | 10 oz./ft² (Special Projects) |

| Hole Size (Minimum Drilled) | .008 in | .006 in |

| Hole Size, Plated (Diameter Tolerance) | +/- .002 in | +/- .001 in |

| Trace / Space Width | .004 inch / .004 in | .003 in / .003 in |

| SMT Pitch | .015 in | Below .015 in |

| Aspect Ratio | 10:1 | Above 10:1 |

| Materials | • *FR4 (Isola) - ED130 / UV - FR402 / FR404 / FR405 - FR406 / BC / N /HR • *Nelco® 4000-2 / 4000-7 • Dupont® - LF and AP series material (flex applications) - *Coolam LX / LA (aluminum backed) • High temperature materials - FR408 (Isola - 180 Tg) - *Polyimide (P95-260 Tg / 35 N - 250 Tg) -*370 HR (Isola - 180 Tg) • High speed application materials - Rogers® *4350 / 4003 - Teflon® (Rogers® Duroid™) - IS680 (Isola) - Arlon 25 N / *25 FR - Ceramic (TMM series, etc.) - BT - *Nelco® 4000-6 / -6 FC • RoHS compliant materials - All Isola / Nelco materials listed above are RoHS compliant (Not intended to indicate lead free assembly compliance) |

Other materials as requested by the customer |

| Final Finish | • HASL (Hot-Air-Solder-Level) • Immersion Silver • ENIG • Selective Gold • Wirebondable Gold |

Other finishes as requested by the customer |

| Manufacturing Minimum Turn Times by Layer for Prototypes | • 2 - 4 Layer - 1 - 2 days • 6 - 12 Layer - 2 - 3 days • 14 - 24 Layer - 3 - 5 days |

Special process and flex applications |

| Manufacturing Turn Times by Volume | • Mid Volume - 3 - 5 weeks • Low Production - 1 week |

High production |