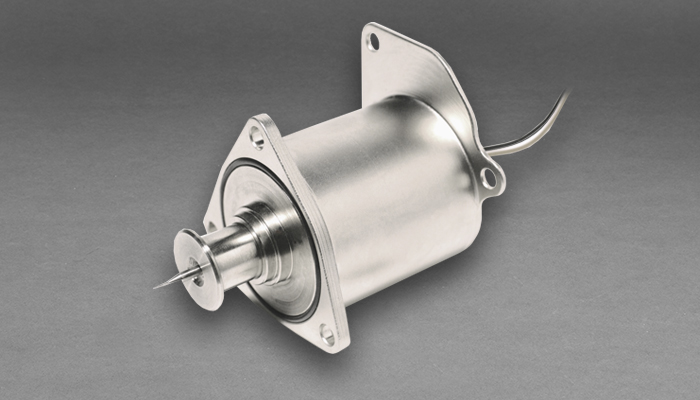

Linear Solenoids

Jump To:

Models and Specifications

Resources

Models and Specifications

Linear Solenoids

| Models | Description | Force - Stroke / Dimensions (inches) | Force - Stroke / Dimensions (millimeters) |

SDHH-2.3UF0.018-80 |

Pull Type | 80 lbf @ .018 stroke @ 13.3 VDC 2.250 diameter x 2.311 length |

355.9 newtons @ 0.46 57.2 diameter x 58.7 length |

| 13330 | Pull Type | 44 lbf @ .250 stroke @ 24 VDC 2.125 diameter x 3.174 length |

195.7 newtons @ 6.35 54.0 diameter x 80.6 length |

| SDUH-1.8UB0.012-26 | Pull Type | 26 lbf @ .0120 stroke @ 13.3 VDC 2.239 diameter x 1.808 length |

115.7 newtons @ 0.31 56.9 diameter x 45.9 length |

| C62840-004 | Push Type* | 15 lbf @ .190 stroke @ 28 VDC 1.510 diameter x 4.577 length |

66.7 newtons @ 4.83 38.4 diameter x 116.3 length |

| SR15130-1 | Push Type | 7 lbf @ .160 stroke @ 13.3 VDC 1.970 diameter x 1.330 length |

31.1 newtons @ 4.06 50.0 diameter x 33.8 length |

| SDUP-1.500WAA-2 | Pull Type* | 4.88 lbf @ .300 stroke @ 24 VDC 1.500 diameter x 2.885 length |

21.7 newtons @ 7.62 38.1 diameter x 73.3 length |

| SR2780 | Pull Type | 2 lbf @ 0.060 stroke @ 24 VDC 1.180 diameter x 1.174 length |

8.90 newtons @ 1.52 30.0 diameter x 29.8 length |

| SR2080 | Pull type* | .11 lbf @ .125 stroke @ 13.3 VDC .687 diameter x 1.969 length |

0.5 newtons @ 3.18 17.3 diameter x 50.0 length |

| SR2000 | Pull type* | .044 lbf @ .250 stroke @ 28 VDC .500 diameter x .625 length |

0.2 newtons @ 3.18 12.7 diameter x 15.9 length |

| SR2070 | Pull type | .022 lbf @ .058 stroke @ 12 VDC .500 diameter x .625 length |

0.1 newtons @ 1.47 12.7 diameter x 15.9 length |

| 5650 | Pull Type* | .022 lbf @ .093 stroke @ 27.5 VDC .375 diameter x 2.327 length |

0.1 newtons @ 2.36 9.5 diameter x 59.1 length |

*Includes return spring