Automotive Test

Increase Your Automotive Test Lab Productivity

Moog automotive testing systems deliver unmatched precision, flexibility, and reliability for validating vehicle performance, durability, and safety. Designed to meet the rigorous demands of modern automotive development, Moog’s portfolio includes multi-axis test systems, 4-poster rigs, simulation tables, and high-performance actuators.

These systems support a wide range of testing applications—from noise, vibration, and harshness (NVH) to buzz, squeak, and rattle (BSR), and full vehicle durability testing. Integrated test controllers and software ensure seamless operation and data accuracy, while hydraulic power units and service manifolds provide robust system support. Moog’s solutions empower automotive engineers to accelerate development cycles, reduce costs, and bring innovative vehicles to market faster.

The Most Reliable Automotive Test Systems

Simulation Tables

Hydraulic and Electric Moog Simulation Tables simulate acceleration and displacement outputs reproducing key data collected on proving grounds. Our integrated control hardware and software provides the most flexible, highest performing test equipment available.

Multi-Axis Test Systems

Compact Electric and Hydraulic Multi-Axis Test Systems deliver highly reliable solutions to a variety of applications, ensuring high level of reliability, flexibility and accuracy in demanding environments.

4-Poster Test Rigs

With a variety of posts offered Moog test rigs can be used with body in white and full vehicles to perform validation, durability, buzz, squeak and rattle (BSR), and noise, vibration and harshness (NVH) testing.

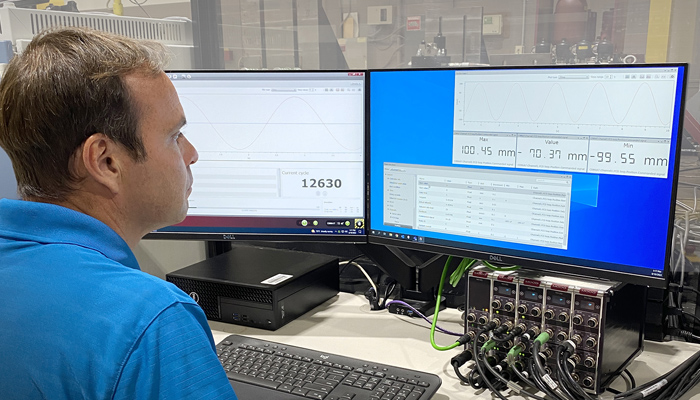

Test Controllers

Test Controllers and software offer maximum flexibility, ease of use, and unprecedented reliability in our hardware and software auto and aerospace test subsystems.