Liquid Cooling Pumps for Data Center Servers

The Importance of Data Center Cooling Pumps: Essential for Efficient Operation

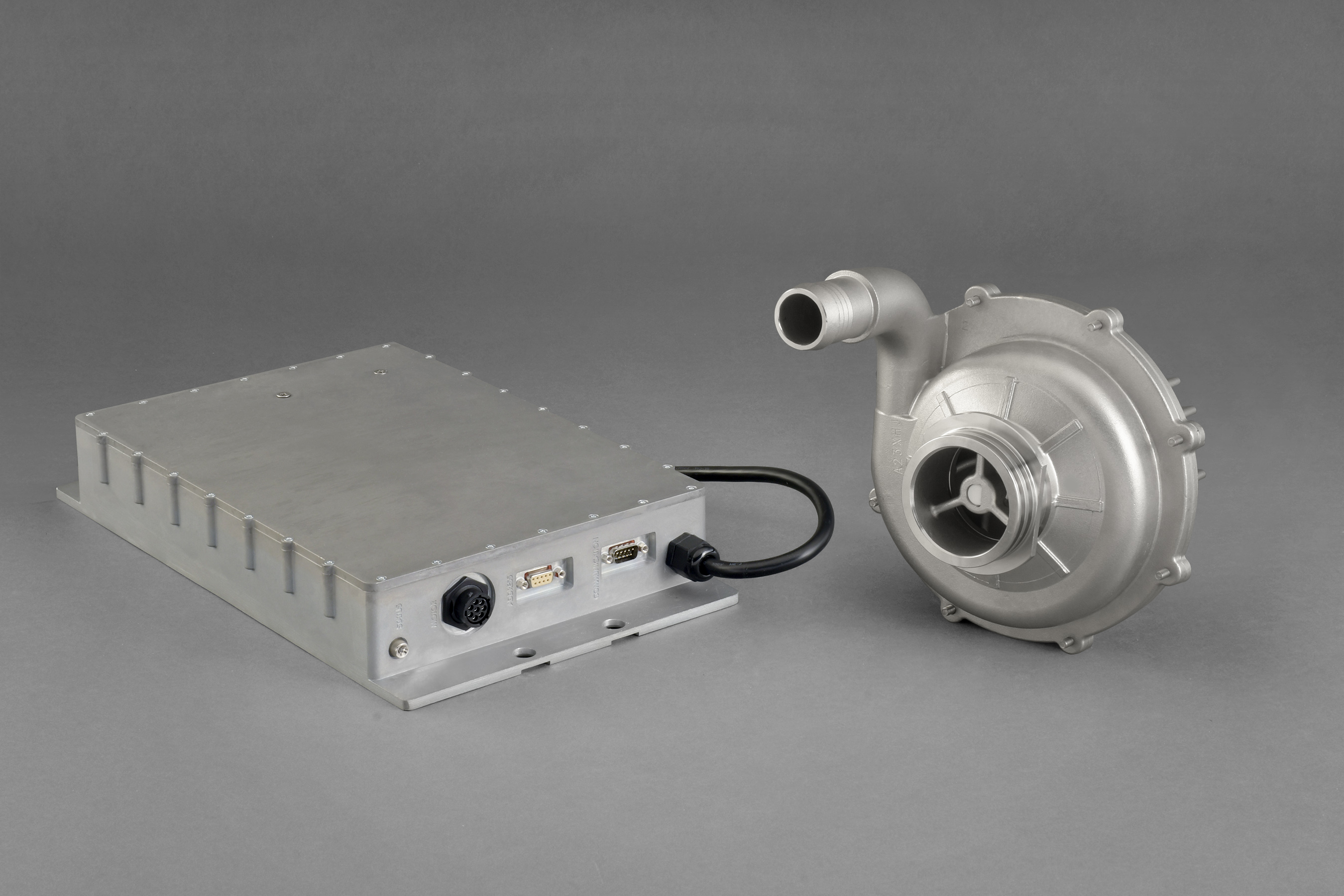

As technology continues to evolve, the demand for efficient, high-performance data centers has never been greater. With an increasing number of servers, higher computing power, and constant data flow, managing heat in data centers has become one of the most critical aspects of operations. This is where Moog’s CoreMotion™ magnetic data center cooling pump comes into play.

The Benefits of Liquid Cooling

Liquid cooling significantly improves Power Usage Effectiveness (PUE) by reducing the energy required to cool data centers, leading to lower operational costs and a smaller carbon footprint. Unlike traditional air cooling, liquid cooling efficiently absorbs and dissipates heat directly from high-performance IT equipment, minimizing thermal resistance and reducing the need for energy-intensive air conditioning.

Advanced solutions like Moog’s CoreMotion™ pumps further enhance PUE by integrating high-efficiency direct-drive motors, variable-speed control, and seal-less magnetic space saving designs, which eliminate unnecessary energy losses and optimize coolant flow in real-time. By utilizing wet rotor designs and using eco-friendly materials and fluids, these systems not only improve cooling efficiency but also contribute to a sustainable, greener data center infrastructure. As a result, organizations can achieve a lower PUE ratio, ensuring greater energy efficiency, reduced costs, and improved hardware longevity all while maintaining performance supporting global sustainability initiatives.

What Makes Moog’s Pump Systems Reliable, Energy Efficient, and Sustainable?

Energy Efficient

Moog’s CoreMotion™ magnetic pump and compatible drive reduces energy loss and eliminates leaks. Moog’s CoreMotion™ cooling pumps also have compact and robust construction with high-density computing, meaning it can accommodate more computing power in smaller spaces.

Reliability

Moog’s advanced pumps are designed to operate in demanding environments, offering more reliability and reducing the risk of system failure. Moog’s CoreMotion™ compact pump allows for N+1 designs ensuring if one pump fails or needs maintenance, the system can still operate effectively without any downtime.

Sustainable

CoreMotion™ pumps are eco-friendly, using less fluid and energy while providing efficient cooling. This means lower energy consumption, reduced carbon footprint, reduced waste from frequent part replacement, eco-friendly coolant compatibility and primarily made of stainless steel, ensuring safer environmental impact.

Fluid Control

Moog’s wet rotor design enhances heat dissipation creating efficient fluid movement and minimal resistance. In addition, Moog’s ultrasonic capabilities provide a means of detecting abnormalities or changes in fluid characteristics within liquid cooling systems, which can detect and be used to intervene with cavitation. For example, air bubbles in the fluid that could potentially harm critical equipment.

Scalable

Moog’s cooling pumps offer variable speed control for adaptive performance. The pump speed adjusts dynamically based on real-time cooling demand to efficiently handle increasing loads and demands as the data center grows. This helps avoid overcooling or excessive power draw, reducing energy waste. It also supports 230/240V AC, 12V DC, and 48V DC operation, optimizing efficiency for different power.

Customizable & Smart System Integration

CoreMotion™ cooling pumps offer multiple communication options enabling ease of integration with AI-driven cooling systems. Additionally, temperature and current feedback sensors optimize performance in real time, which provides leak detection technology preventing inefficiencies caused by system failures.

Durability & Maintanence

Moog’s Cooling pumps are built to last, with no wear parts. Once it’s installed, it’s done – no downtime and no maintenance required.

Reliable Liquid Cooling at Scale

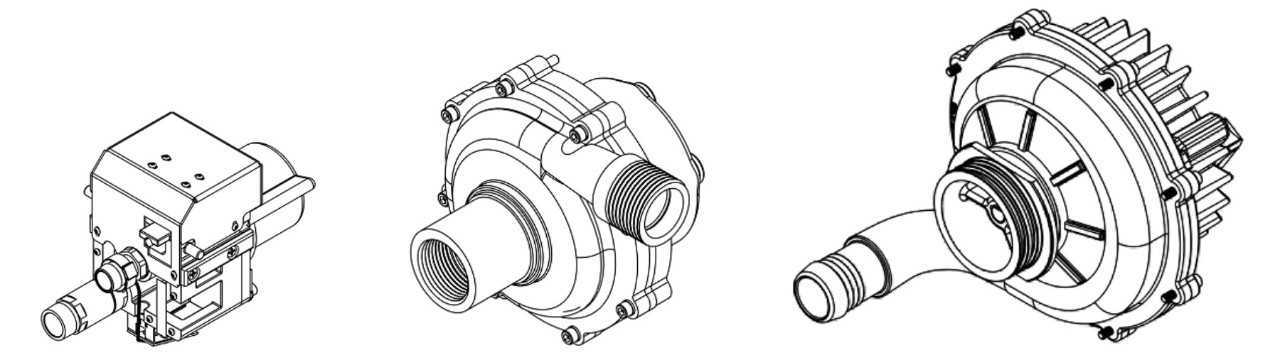

Moog liquid cooling pump designs offer different frame sizes and matching intelligent controls.

| Model | Input Voltage | Power | Variable Speed | Flow Rate Range (GPM) | Pressure Range (PSI) | Certifications |

| RS23 | 12 VDC | 120 watts | 1,050 - 4,200 rpm | 0.5 - 7 | 0.5 - 7 | Contact factory |

| RM30 | 48 VDC | 480 watts | 430 - 4,300 rpm | 5 - 37 | 12 - 26 | Contact factory |

| RM44 | 230 / 340 VAC | 2.5 kW | 1,070 - 4,300 rpm | 10 - 65 | 35 - 65 | Contact factory |

| CM400 | 380 - 416 VAC | 37 kW | 430 4,300 rpm | 250 - 500* | 25 - 112 | UL 778, UL 61800 |

Contact a Moog expert to discuss sizing options and latest innovations in development.

All related technology is proudly owned by Moog.

Engineering the future of cooling.

Literature

Related Products