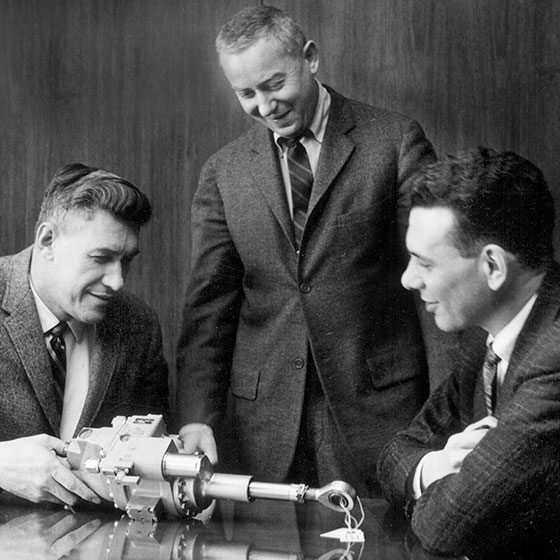

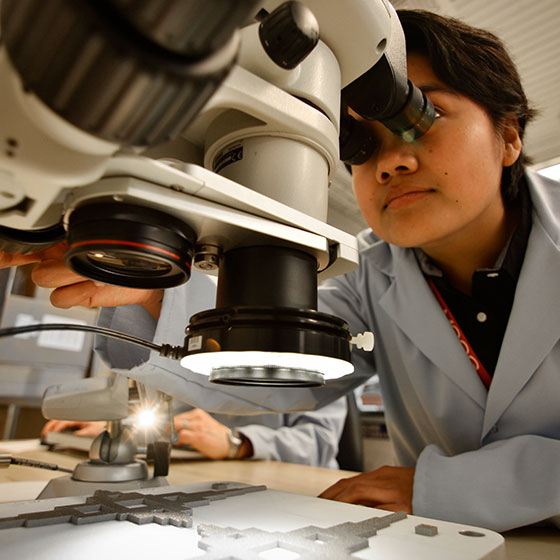

About Moog

About Our Business

Military Aircraft

World leader in flight control systems and critical control products for military aircraft and rotorcraft.

Space and Defense

Premier motion and flow control solutions provider for the space and defense industries.

Industrial

Differentiate your next generation machine with our high performance motion control products, solutions and services.

Commercial Aircraft

World leader in flight control systems and critical control products for commercial aircraft and business jets.

We Are Built On Our Culture and Values

-

![Column Item]()

TRUST IS A MUST

We hold ourselves to the highest standards of integrity and honesty.

-

![Column Item]()

COMMUNICATION IS CRUCIAL

We believe that trusting relationships are built through open, honest, and complete communication regardless of our role.

-

![Column Item]()

WE'RE ALL IN THIS TOGETHER

We share in our success and challenges as ONE Moog.