What is “In Space Assembly and Manufacturing” (ISAM)? How is it used?

In-Space Servicing, Assembly and Manufacture (ISAM) serves as a comprehensive descriptor for a wide range of functions conducted in space. NASA has published a survey of past, present, and near future ISAM capabilities across industry and government agencies in their "ISAM State of Play" document.

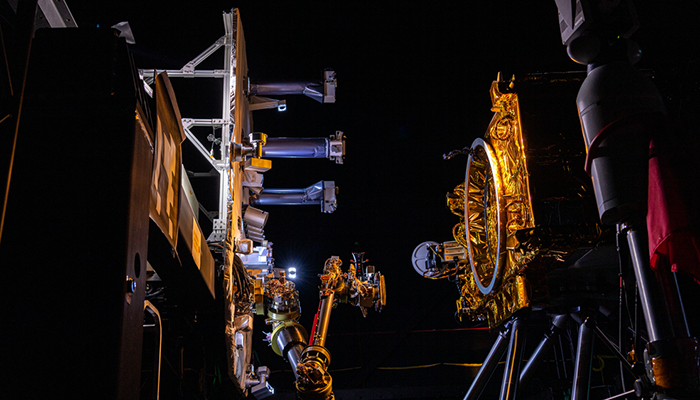

New robotic solutions are being conceptualized and pushed into development to revolutionize the way we build and operate spacecraft. These advancements open new possibilities for both autonomous and human-rated exploration and settlement in space.

During a panel at the 38th Space Symposium in April 2023, Jim Reuter, NASA Associate Administrator for Space Technology, announced the creation of a new organization, called COSMIC, devoted to advancing these technologies.

“Our goal for COSMIC is to accelerate the universal adoption of ISAM capabilities to develop the next generation of space architectures and make ISAM a routine part of the space enterprise,” said Reuter.

The U.S. civil and commercial sector are not pursuing ISAM in isolation. Within the US DoD, ISAM is synonymous with Space Access, Mobility, and Logistics (SAML). Globally, space agencies in the UK (UKSA), Europe (ESA), and Japan (JAXA), among others all have emerging initiatives to support the proliferation of sustainable in-orbit servicing (IOS) solutions.

Why is Moog pursuing this opportunity?

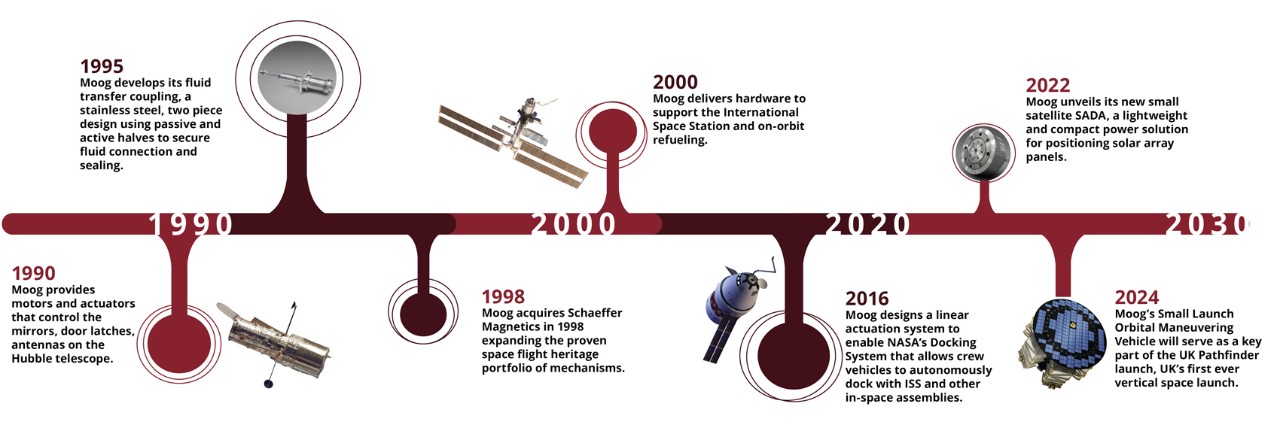

Moog has provided component and system-level solutions to what we now call ISAM for decades. All Moog space businesses and locations provide ISAM-enabling technologies. As an industry-leader in actuation, avionics, mechanisms, propulsion, structures, and shock and vibration isolation, Moog offers a unique suite technical expertise to offer customers. Looking at the future of this market, Moog’s Advanced Programs & Innovation team is working to offer a system level or higher catalogue and custom solutions to meet any of our customers’ needs with affordable, accessible, and scalable solutions. Additionally, we are collaborating with businesses of all sizes, universities, and government organizations around the globe to conceptualize and design prototypes to today to establish robust ISAM systems for commercial and military (defense) needs.

Moog mechanisms allow for robotic, autonomous manipulation of elements in space. Moog actuation, fluid coupling, and transfer systems have been designed, launched, and used in space to provide fluids and gases to Atlas II & III, Space Shuttle, and International Space Station (ISS) Thermal Control System. Our Non-bellows rotary shut off (RSO) & Rotary Assist Type RSO couplings have heritage on ISS and are standard interfaces for RSO & rotary motor drives. Moog’s family of fluid transfer couplings (FTC) are suitable for cryogenic and non-cryogenic media. Moog FTC is also compatible with all in-space propellants such as classic hydrazine but also green propellants (i.e. ASCENT and LMP-103S). Moog FTC products will also be launched on Gateway.

Moog also designed and delivers the Linear Actuation System (LAS) to NASA for NASA Docking System (NDS). Moog’s LAS is part of the Soft Capture System (SCS) subsystem. The Moog hardware will be flown on the Boeing CST-100 Starliner and will dock with the ISS allowing the crewed vehicles to dock autonomously. Moog is currently updating this system to be compatible in the deep space environment and will be used on the Orion Spacecraft, Artemis, and at the Lunar Gateway.

What brought this need / what problem are we solving?

One of the key challenges faced by the space industry is the high cost of launching and maintaining satellites. ISAM missions seek to address these challenges by enabling repairing, refueling, and extending the lifespan of satellites on-orbit, and even assembling telescopes and other large structures in space. Robotic technologies can allow this to be done without the need for expensive and risky human missions. By reducing the overall cost of space exploration, we can better protect the assets on which our global civilizations rely.

Moog is already supporting ISAM missions, including OSAM-1 and aligning ourselves to be a prominent player in future missions. Future ISAM missions are really looking to make what was once thought to be impossible in space possible.

If you’re interested in speaking to Moog about our In-Space Servicing, Assembly, and Manufacturing (ISAM) solutions email Jason Jones at jjones8@moog.com or Vince Ferrante at vferrante@moog.com