Air Moving Product Development:

Design, Engineering, and Testing

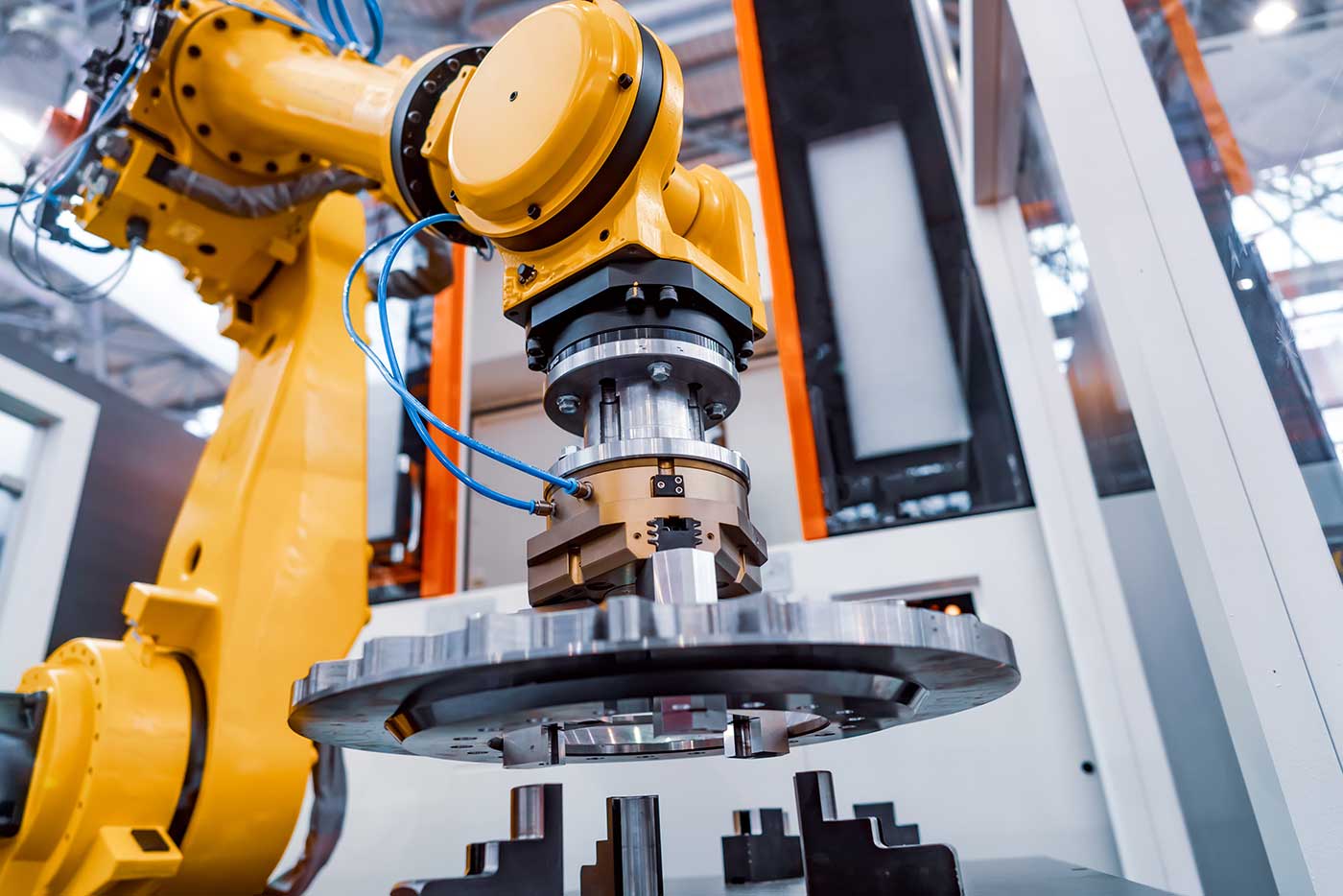

Design and Engineering

System engineers face several problems when attempting to specify an air moving device. Several key factors to be considered are:

- Airflow Required

- Static Pressure

- Power Available

- Positive or Negative Pressure

- Acoustical Limits

- Control & Alarm Options

- Air Filtration

- Reliability/Redundancy

- Cost

- Environmental Conditions

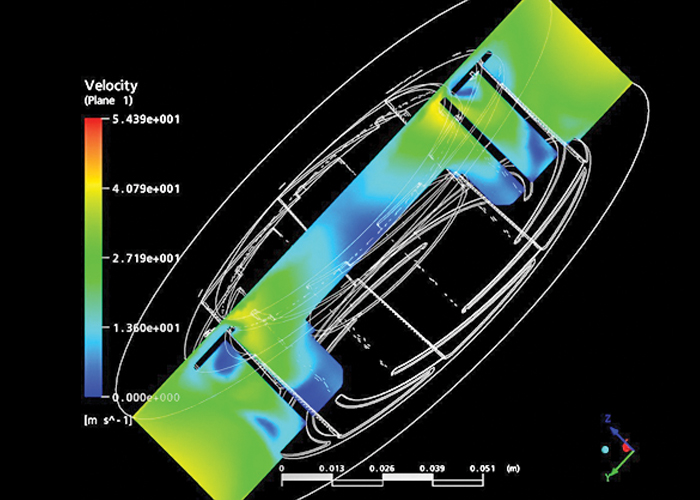

Airflow Testing

Helping our customers determine cooling requirements and optimizing system level cooling, distribution and component temperatures is one of the keys to your success. Moog has complete airflow analysis and testing capabilities. Our early involvement with system level cooling selection prevents surprises late in the design cycle.

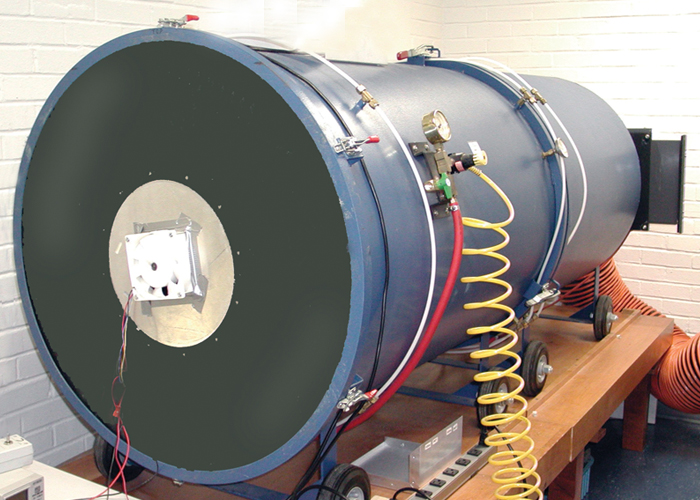

Environmental Testing

Moog has state-of-the-art environmental chambers that can verify whether the designed unit will work reliably at all temperature extremes from -73°C to 175°C. In addition, we can do extended temperature testing on most systems with the air movers installed to ensure an overall system reliability. Humidity, salt fog, shake and vibration testing is also available.

Safety and Compliance

We have successfully designed and manufactured products certified by UL, NSF, ETL, TUV, CE and other emerging market requirements.