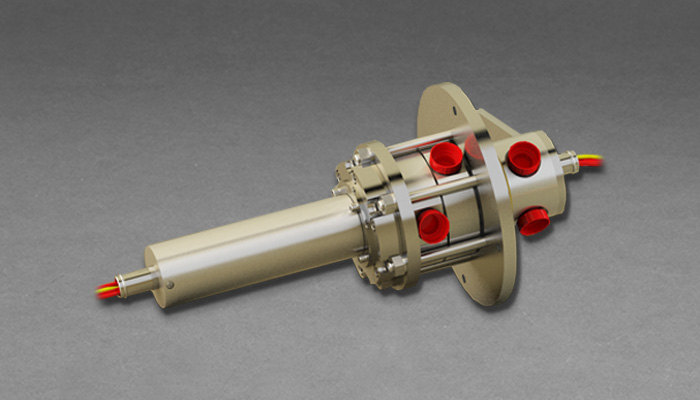

Model 200 Hybrid ESR / FRU with Optional FORJ

Jump To:

Overview

Specifications

Resources

Related Products

The FRU portion is typically configured with up to 13 passes, inter-port mixing is prevented through the use of double seals and an intermediate vent between passes. It is available in several standard port configurations or types. It is available with the standard seal technology or with a new low leakage seal option. In its standard configuration, it is rated for 1000 psi [68 bar] at 10 rpm continuous service and up to 30 rpm intermittent service.

The ESR portion is comprised of power and signal electrical passes. Ideal for small systems, it is a compact, rugged unit designed for harsh operating conditions. For the hazardous area environment, there is an option for a fully certified flame-proof enclosure. When underwater operational capability is required, the it can also be adapted for use as a fluid-filled pressure compensated unit.

The FORJ portion can be configured with any of Moog’s single channel or multi-channel singlemode or multimode catalog fiber joints. Our FORJs are capable of working with all fiber types, sizes and the wavelengths and meet insertion loss performance typical of customer requirements. In addition to FORJs operating at standard wavelengths for data communication, FORJ versions have been developed to work with optical sensors with enhanced optical loss and return loss over a broader range of wavelengths. Moog has been the leading supplier of FORJ products to the marine industry for over 20 years with many thousands of products delivered to the oil and gas markets. For the oilfield market, products are designed to be robust and weatherproof with all models being shock and vibration tested and options for operating fluid-filled and pressure compensated.

Features

- Electrical passes rated up to 1500 V / 7 A

- Hazardous area certification available

- Configurable with up to 13 ports as standard

- 1/4, 1/2, 5/8 and 1 inch SAE straight thread o-ring ports standard

- Corrosion resistant materials suitable for hot sea water and other harsh chemicals

- Rated to 1000 psi [68 bar] at 10 rpm continuous service

- Maximum speed 30 rpm intermittent

- Polymer bearings eliminate the need for periodic service

- Optional rolling element bearing design available

- Sealed housing design tested to IP 66 standards

- Can accommodate a variety of wire and cable types

- Rugged design

- Reliable operation under shock and vibration

Benefits

- Low leakage

- Configurable

- Integrated assembly for ease of installation

- Compact size

Typical Applications

- Diving umbilical winches

- Seismic survey winches

- Hydraulic and electric control winches

- Remote Operated Vehicles (ROVs)

- Winch applications

- Mine countermeasures

- Towed instrument arrays

- Wirelining

Specifications

| Model 200 Specifications | |

| Ambient Temperature Gases Liquids |

40°C to +60°C -40°C to +100°C 0° to +60°C |

| Pressure1 | 1000 psi (3000 psi optional) |

| Weight | Dependent on configuration |

| Rotational Speed1 | 10 rpm max continuous 30 rpm max intermittent (dependent on configuration) |

| Torque2,3 | Consult product specific installation drawing. Operating torque varies based on number of passes, shaft diameter, pressure, speed, medium and seal type |

| Leakage, Standard Seal | 50 std. mL / min N2 gas per seal rotating @ 1,000 psi max. Typically less than 10 std. mL / min N2 gas per seal rotating @ 1,000 psi |

| Leakage, Reduced Leakage Seal | 2 std. mL / min N2 gas per seal rotating @ 1,000 psi max. Typically less than 0.05 std. mL / min N2 gas per seal rotating @ 1000 psi |

| Nominal Port Size 1/4 inch 1/2 inch 5/8 inch 1 inch |

SAE straight thread O-ring thread size 7/16-20 UNF 3/4-16 UNF 7/8-14 UNF (passage size suitable for 3/4” nominal, 1-1/16-12 UN adapter)1-5/16-12 UN |

1Operational life is dependent on pressure, temperature, rotational speed duty cycle and size of assembly. Maximum values do not apply concurrently. Please consult the factory for actual value.

2Break-in torque may be higher

3Flexible conduit should be used to couple to the rotating component. The torque arm must be loose coupled.

Resources

Literature

Data Sheets

Technical Support

Telephone: +1-902-468-2263