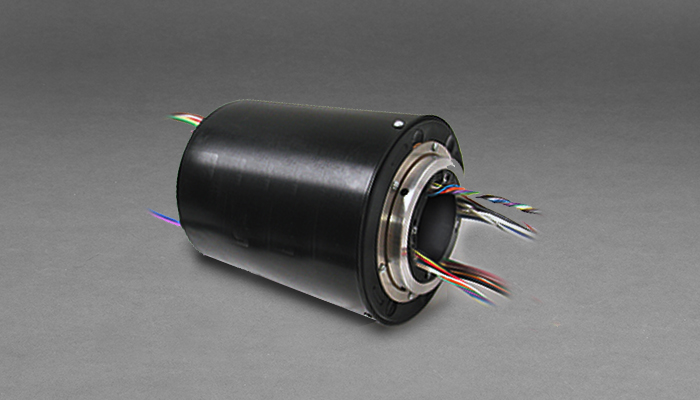

AC6200

1-1/2 INCH THROUGH-BORE 12, 24, 36 AND 48 CIRCUIT VERSIONS

A slip ring can be used in any electromechanical system that requires unrestrained, continuous rotation while transferring power and/or data from a stationary to a rotating structure. A slip ring is also called a rotary electrical interface, collector, swivel or a rotary joint. A slip ring can improve system performance by simplifying operations and eliminating damage-prone wires dangling from movable joints. The 1-1/2 inch unobstructed through-bore provides routing space for hydraulics, pneumatics or for a concentric shaft mount.

The AC6200 slip ring with through bores uses fiber brush technology which offers several advantages over conventional slip ring contacts including multiple points of contact per brush bundle, low contact force per fiber and low contact wear rates. In addition, fiber brushes do not require lubrication and produce virtually no wear debris, for maintenance free, life time operation.

Features

- 1-1/2 inch through-bore

- Speeds up to 250 rpm

- 12, 24, 36 and 48 circuit versions with 2 amp / 220 VAC contacts

- Power and signal (10 and 2 amp) circuits may be combined

- Shaft, brush block and cover are molded of high-impact thermoplastic

- Optional steel bearing and splash seals for harsh environments (special order)

- Collar mounting is standard; flange mounting optional

- 26 gauge color coded, 12” lead wires

- Continuous 360° rotation of power or data signals

- Also available with 6, 12 and 18, 10 amp / 600 VAC rings.

Please refer to AC4598 product information - Silver plated rings, silver alloy brushes

- Available with Ethernet

Benefits

- Transfers control and data signals

- Fiber brush technology provides maintenance-free operation (no lubrication required)

- Modular design meets special requirements through off-the-shelf manufacturing techniques

- Compact packaging

Options

- 5 inch O.D. flange with 4 mounting holes

- Splash seals for dust and moisture resistance

- Various axial and radial lead exits are available

- Signal and power circuit combination for

- 10 A / 600 VAC applications

- Gold plated rings

- IP 65 rated enclosure available (P/N AC6419)

Typical Applications

- Industrial machinery – machining centers, rotary index tables, heavy equipment turrets or cable reels, test equipment, packaging and palletizing machines, magnetic clutches, process equipment, rotary sensor, emergency lighting, robotics

- Exhibit / display equipment

- Medical equipment