Advanced Manufacturing

Advanced Manufacturing Highlights

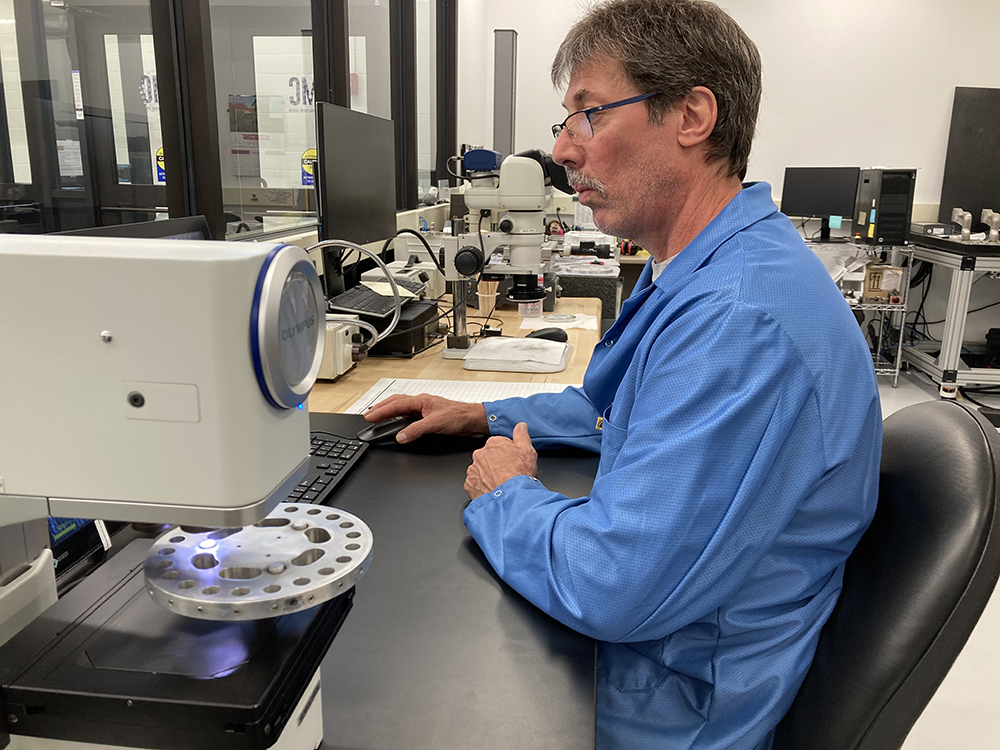

Moog Advanced Manufacturing Using Artificial Intelligence

Moog continues a strong tradition of innovation to revolutionize manufacturing. We are making complex metal parts through a metal additive manufacturing process called Laser Powder Bed Fusion. It allows engineers to create more complex parts than ever before and promises to increase the performance of systems using additively manufactured components or assemblies. Now, we’re deploying Artificial Intelligence to help inspect the quality of work.

Moog Additive Manufacturing Supporting University of Buffalo Student Nanosatellite FALCON Project

The University of Buffalo’s Nanosatellite Laboratory (UBNL) is building two satellites to test line of sight formation flying. This project is sponsored by the Air Force Research Lab. Moog Additive Manufacturing Center donated structural hardware to fly on these student built satellites. Excellent work FALCON (Formation Attitude Laser Communication Orbital Navigator) team!

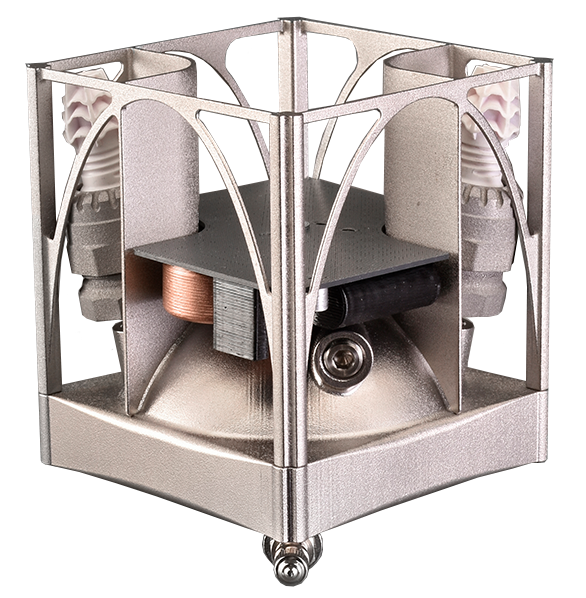

Monopropellant Propulsion Module

The Moog additive manufactured small liquid monopropellant blowdown propulsion module is suitable for cubesats and small satellites that require attitude control or delta V maneuvers. This is an all-digital design leveraging Moog additive manufacturing and propulsion equipment design expertise.

Additive Manufacturing for Space

Moog has a strong heritage of providing thrusters and associated components to global satellite customers. To prepare for the ever-evolving space market, Moog has invested in a state-of-the-art metal Additive Manufacturing (AM) facility and a new engine testing facility.

Currently, Moog engineers are developing technologies to support the next generation of monopropellant and bi-propellant small thrusters, utilizing AM and other advanced manufacturing methods. AM offers unique geometries that increase propellant flow efficiencies and provide unparalleled thermal management. Within one-half inch, a thruster could have a surface that will be greater than 2500˚ F and another feature that needs to be maintained to less than 100˚ F. The additive configuration allows for these temperatures to be accommodated where traditional manufacturing methods would not meet the expected package requirements.

When compared to a conventional design method, additive offers the advantages of weight reduction, overall part-count reduction, reduced special processes such as welding and brazing, faster design iteration with shorter lead-times, and improved performance with a potential for lower cost products. Moog has recently manufactured, and hot-fire tested AM rocket engine injectors made of titanium and INCONEL®. Traditional or subtractive machined parts have a lead-time of 12-15 months. Moog’s AM rapid product development reduced the lead-time to 4-6 months, with a replacement part lead-time of 4 days. Complex geometry due to injector complexity, envelope, and mass constraints made AM development the answer for a hardware design that had to meet strict customer performance specifications.

News, Articles, and Blogs

Building on Additive: From Operating Group to Enterprise and Back

Smart factory initiatives often involve complex projects and new technology deployments, even before adding in the complications faced in 2020. How are leading manufacturers managing smart factory advancements strategically in this climate? Earlier this fall we spoke with Bill Massaro, Director of Advanced Manufacturing in the Aerospace and Defense Sector at Moog, to learn from his experience.