Precision targeting, stability and control and agility: The three elements for a successful divert and attitude control system

The Challenges for Missile Defense Systems

Emerging threats mean missile defense systems have to constantly evolve to develop new technologies and tactics to stave off adversaries on land, air and space. Developing systems that can accurately detect, track, and intercept missiles in real-time is highly complex. This includes dealing with the speed and maneuverability of modern missiles, such as hypersonic weapons. Addressing these challenges is crucial for maintaining effective missile defense capabilities and ensuring national and global security.

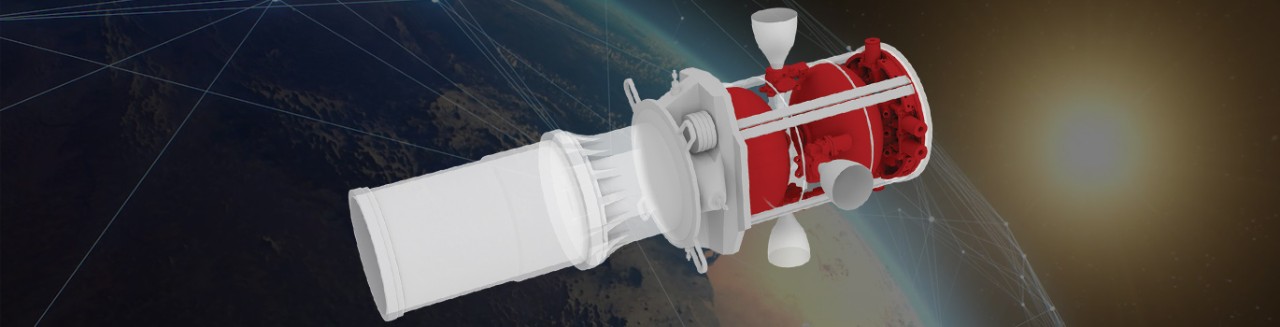

DACS as a Critical Element for Missile Defense

The need for advanced maneuvering capabilities in interceptor missiles became apparent with the increasing threat of ballistic missiles, particularly highlighted during the Gulf War in the early 1990s. The U.S. Department of Defense and Missile Defense Agency (MDA) recognized the importance of fast-acting propulsion systems for controlling missile positioning. The MDA sought new lightweight, erosion-resistant components and storable propellants for divert and attitude control systems (DACS), prompting companies to develop innovative solutions. DACS technology has evolved over time, with continued research and development aimed at improving performance, durability, and cost-effectiveness.

A DACS is a critical component in missile and spacecraft technology, particularly in systems that require high velocity, precise maneuvering, and orientation control, because it steers an interceptor through the final intercept trajectory. DACS are essential pieces of any missile defense plan because they ensure interceptors can adjust their flight paths quickly and precisely while maintaining stability to neutralize threats that often appear suddenly and move unpredictably.

The liquid divert control aspect of DACS is responsible for changing the trajectory or path of the missile or spacecraft. This is crucial for intercepting targets, avoiding obstacles, or making course corrections. Using storable propellants enable the military assets to stay dormant for years until called up for engagement. The attitude control aspect of DACS is responsible for maintaining or changing the orientation of the missile or spacecraft. This ensures that the vehicle is pointed in the correct direction for navigation, communication, or targeting purposes.

How it Works

The most critical elements of a DACS are the thrusters that change the vehicle’s position, sensors that determine orientation, and the avionics that control the thrusters and process sensor data. Divert control typically involves the use of small thrusters or engines that can produce thrust in various directions. These thrusters are strategically placed around the vehicle to provide the necessary force to change its path. The thrust can be generated using different types of propellants, such as liquid, hybrid fuels and solid depending on the specific design and requirements of the system.

Attitude control is achieved using reaction control thrusters, control moment gyroscopes, or reaction wheels. Reaction control thrusters work similarly to divert thrusters but are used to rotate the vehicle around its center of mass. Control moment gyroscopes and reaction wheels, on the other hand, use the principles of angular momentum to control the vehicle's orientation without expelling propellant.

The DACS relies on a combination of sensors to determine the current position and orientation of the vehicle. These sensors feed data to the guidance system, which calculates the necessary adjustments to achieve the desired trajectory and orientation. The guidance system uses complex algorithms to process the sensor data and determine the precise amount of thrust needed from each thruster. These algorithms take into account factors such as the vehicle's mass, velocity, and external forces (e.g., gravity, atmospheric drag). Once the guidance system has calculated the required adjustments, it sends commands to the thrusters to fire in specific sequences and durations. The thrusters then produce the necessary forces to change the vehicle's path and orientation.

Moog’s heritage and future investments are ready for DACS needs

Moog has been a trusted leader in Divert and Attitude Control Systems (DACS) for decades, delivering high-precision components and complete systems for missile defense. Our engineering teams specialize in robust thruster design, propellant management, and integrated guidance, navigation, and control solutions, driven by continuous investment in research and development.

To meet the growing demands of commercial and government customers, Moog has expanded facilities, enhanced capabilities, and upskilled its workforce. With more than 70 years of precision motion control expertise, we remain committed to innovation and quality across our seven U.S. space sites, supporting next-generation national security missions.

At our Niagara Falls, NY propulsion facilities, Moog produces monopropellant and bipropellant engines, as well as high delta-V integrated chemical propulsion systems. Recent upgrades to hot fire test cells and clean rooms support larger thrust classes and rapid prototyping. Our East Aurora, NY headquarters complements this work by manufacturing critical components, like valves, for thrusters and integrated systems.

To stay ahead in the evolving space market, Moog has established a cutting-edge Additive Manufacturing (AM) Center. This facility enables advanced thruster designs with improved flow efficiency, thermal management, reduced weight, and faster iteration, delivering high-performance, cost-effective solutions.

Moog also added 120,000 square feet at our headquarters for engineering and production of precision motion control actuation and avionics systems. The new facility increases production capacity and brings together development, production, and testing of electromechanical, electrohydrostatic, and electrohydraulic actuation systems solutions. The integrated building and layout design is a unique differentiator, matched by few in the industry, to offer an enhanced customer focus, reducing hand-offs throughout the manufacturing lifecycle, improving both quality and lead times.

The avionics facility in Gilbert, AZ has continued to advance its radiation-hardened computing and power solutions to be able to withstand long durations the harshest environments. Moog unveiled its next-generation Cascade Single Board Computer that will offer 10-100x processing speeds for bus and payload applications for all orbits.

Rigorous quality assurance processes ensure reliability under extreme conditions. Missile defense systems must continuously evolve to counter emerging threats, with DACS playing a pivotal role in ensuring precise maneuvering and stability. The integration of advanced thrusters, sensors, and avionics allows interceptors to effectively neutralize unpredictable threats.

Finally, investing in our people is central to the Moog mission. In 2025, the Moog team grew to 14,000 employees worldwide. In August 2025, Moog also opened its new, 13,000-square-foot Operations Training Center to provide hands-on training and career development paths. It ensures the advanced manufacturing workforce can meet the growing manufacturing capacity demand for important national defense projects within the aerospace and defense markets.

As space becomes the ultimate high ground, Moog continues to invest in the technologies and talent needed to support those who defend freedom and explore the universe, protecting our most critical assets.

Blog Links:

Moog Golden Dome Capabilities

Moog DACS