In this article:

- ATEX Digital Interface Valves offer flexible, high efficient motion control for use in hazardous environments

- Rugged valve construction and advanced functionality are ideal for applications such as downhole drilling with vibration and heavy use

- Moog helps customers find benefits for their applications using digital valve technology

New Moog Servo Valves with Fieldbus and ATEX explosion proof certification used in Oil and Gas Drilling Applications

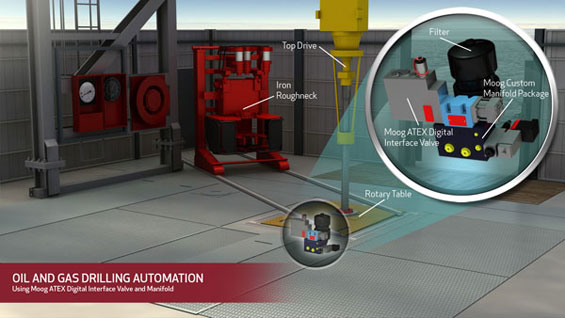

Oil and Gas Drilling Automation Using Moog ATEX

Digital Interface Valve and Manifold

Oil and gas drilling represents one of the world’s most extreme operating environments. Reaching deep below the surface, under heavy use and constant vibration with the looming potential to release underground gas pockets takes a significant toll on drilling subsystems. To offer machine builders better options in motion control technologies, Moog expanded its successful Digital Interface Valve Family of servo valves with onboard microprocessing to meet the rugged requirements for applications in hazardous environments such as oil and gas drilling. These valves combine a rugged construction with fieldbus functionality to offer customers around the world the ability to communicate seamlessly with other fieldbus devices and obtain advanced functionality and system diagnostics.

What is an ATEX or explosion-proof Valve?

There are a range of certifications required for products used where fire or explosion hazards exist due to the presence of flammable gases or vapors, and flammable liquids. ATEX is a global certification for products such as servo valves that are used in these environments and it is typically required by companies that sell into the European Union. A range of levels is defined by the regulations ( e.g. II 2G Ex d e IIC T6/T5/T4/T3 Gb) and Moog engineers will work with you to obtain the performance you need and ensure compliance to appropriate regulations

The new valves have been ATEX certified to meet the safety requirements for explosive gas atmospheres. To ensure these valves can withstand high vibration, Moog completed the qualification for vibration transmission and tested the valve (according to DIN EN 60068-2-6) with 10 g sinusodial vibration from 10 Hz to 2000 Hz in all axes.

The Application and its Challenges

To better understand how an ATEX Digital Valve can benefit a machine builder, we will describe a recent application that Moog worked on with a major energy systems company looking to improve the way they control a large hydraulic motor in a drilling subsystem. Although the pressure and flow rates were easily achieved at 210 bar (3,000 psi) and 190 lpm (50 gpm ) respectively, the drilling environment is demanding with heavy use, constant vibration and the potential to release underground gas pockets.

Initially, the request was for advanced flow control to dynamically control the hydraulic motor speed with minimal pressure drop and to reduce piping connections. While working with the customer’s engineers, Moog also learned that future systems could benefit from pressure control that would allow repeatable output torque at slow speed.

ATEX Digital Valve and Custom Manifold Package

Greater Functionality Drives New Opportunities

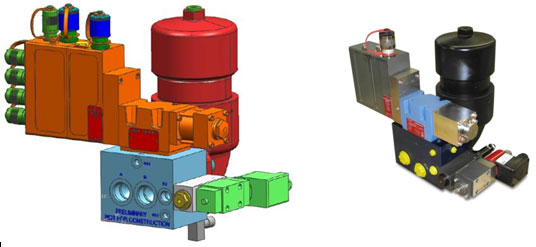

Moog's unique solution consists of the single stage ATEX Digital Interface Valve with a unique 4-way spool configuration and a custom manifold package, consolidated piping connections with mounting for the servo valve, a solenoid valve, backpressure valve and a drainable pressure filter.

In the ATEX Valve, sensors coupled to onboard electronics provide closed-loop control for both flow and pressure which correlate to highly accurate control of speed, torque, position and force. In the past, only pressure or flow control with Moog's explosion proof valves was possible. Now with the new valve series both pressure and flow control are possible with one valve, offering machine builders new opportunities in motion control.

The application evolved over time as more functionality of the digital valve was used. Initial models provided proportional flow control with a 4-20 mA analog interface. Later configurations used more advanced valve features with combined flow and pressure control (pQ control) and the Profibus-DP® fieldbus interface. The pQ configured valve is capable of closed-loop speed control through the hydraulic motor’s encoder and closed loop pressure control through a pressure sensor within the valve for active control of the motor’s output torque.

Why did the customer select Moog?

- Inventor of the first commercialized Servo Valve with 60 years of application experience

- Performance based solutions - tailored to advanced application requirements

- Specialize in motion applications for hazardous environment including the oil and gas drilling, power generation, and test.

- World wide support by experts in motion control

The manifold package and internal passages were modelled in 3D which was used for fluid velocity and internal stress validation to insure calculated pressure drops and a 4 to 1 factor of safety could be maintained. Once validated, the customer directly imported the detailed Moog solid model into their higher level system schematics.

How Does the ATEX DIV Work?

Control electronics are completely integrated within the ATEX Valve, incorporating a microprocessor-based system for executing all key functions via embedded software. This offers flexibility for the valve to adapt to a wide range of operating conditions while maintaining high accuracy and repeatability. In particular, it enables highly optimized system performance even with significant variations in pressure and temperature.

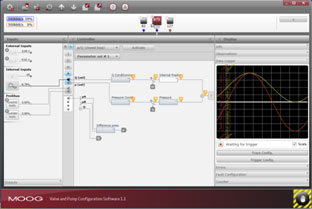

User interface of Moog Valve and Pump

Configuration Software

Since control parameters may be downloaded using the fieldbus or a high level PLC program, the valve control function can be tuned during the machine operating cycle. Integrated continuous monitoring of a range of important valve and system functions and remote diagnostics are possible.

With an electrically isolated fieldbus interface, valve parameters can be changed on site or remotely. The built-in fieldbus interface (e.g. CANopen®, Profibus-DP® or EtherCAT®) enables adjustment of operating parameters, controlling the valve and monitoring of performance. In a safe, private or virtually private network, you can communicate directly with the valve from anywhere in the world. These valves are also available in a version without a fieldbus interface that is controlled using analog inputs and includes a service connector for setting parameters.

To reduce downtime due to installation and maintenance, Moog incorporates a unique feature in the ATEX Digital Interface Valve Series called hot plugged connector capability which enables the user to connect and disconnect the valve with the electrical supply switched on. These connectors are the result of a close collaboration between Moog and a supplier to meet the high demands in terms of shock and vibration. For use in rough environments (e.g. off-shore applications) all provided power and data cables are mud-protected.

The Benefits of the Digital Interface Valve

- Rugged and reliable hardware with explosion proof certification (ATEX) to withstand the constant vibration up to 10g

- Flexibility to easily interface with existing control system

- Advanced motion control functions such as active control of the hydraulic motor's output torque

- Increased valve functionality replaces the need for multiple valve types, providing weight and space savings in the machine

- No need for tuning in the field as it is factory calibrated using software, thereby reducing commissioning time

The Result

Initial builds of the system were completed in 16 weeks from date of order with seamless integration during startup. The new version of the Moog Valve Configuration Software helped make setup, diagnostics and tuning easier. The success in the initial application has led to new projects in areas where proportional control was not typically used.

Background on the ATEX Digital Valves

The ATEX Digital Interface Valve series is available in a full range of sizes. Direct driven valves are available in sizes 03 and 05 (according to ISO 4401) and pilot operated valves are available in sizes 05 to 10 and the maximum operating pressure is 350 bar (5,000 psi).

The valves are certified according to ATEX guideline II 2G Ex d e IIC T6/T5/T4/T3 Gb – which defines various environmental conditions of the locations where the product will be used. The products can operate reliably in range of -20 to +60 °C (-4 to +140 °F) for ambient temperature and -20 to +80 °C (-4 to +176 °F) fluid temperature. These temperature ranges depend on certified temperature classes according to ATEX. Applications for low temperatures down to -40 °C (-40 °F) are also available upon request. The IP protection class is IP66. For easy configuration and parameterization, the Moog Valve Configuration Software is provided free of charge as part of the product package.

Authors

Thomas Röhlig started at Moog GmbH in 2006 as Development Engineer for hydraulic pumps, with responsibility for mechanical design and construction. Mid 2009 the field of responsibility for mechanical design and construction has expanded to servo and proportional valves. He studied Mechanical Engineering at the University of Applied Sciences of Jena, Germany.

Kevin Kolmetz started at Moog in 2011 as Product Sales Manager for the Topside Oil & Gas Market. Kevin has spent 11 years supporting electro-hydraulic & pneumatic actuation needs of customers in the aerospace, defense & industrial markets. He has completed degrees in mechanical engineering and new product development from Rochester Institute of Technology, Rochester, NY USA.