Rotary Mechanical Actuators

Rotary Mechanical Actuation Applications

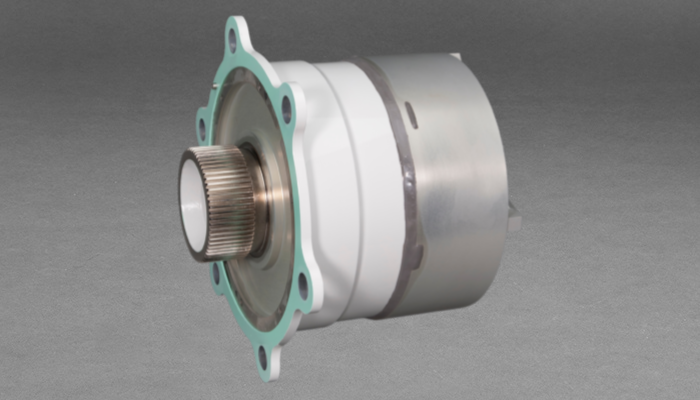

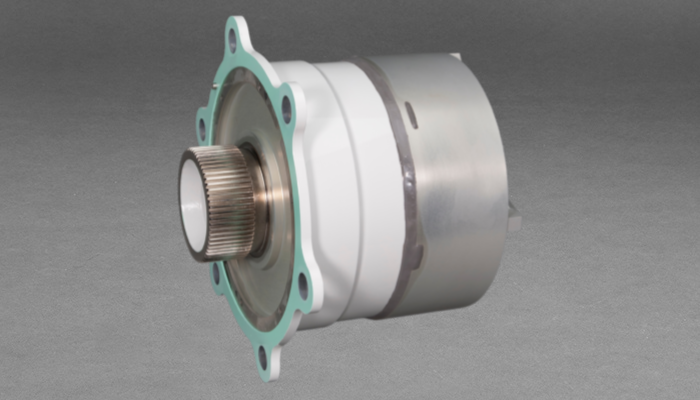

Planetary Geared Rotary Actuator

Simple planetary actuators are most commonly used for commercial leading edge slat applications while compound differential planetary actuators offer higher ratios for torque multiplication and are most commonly used for trailing edge flap designs.

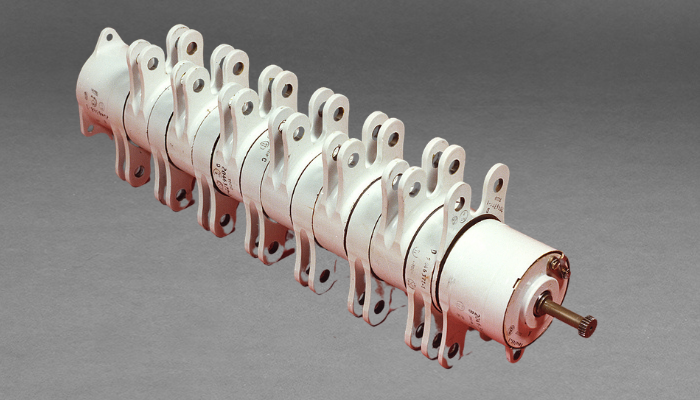

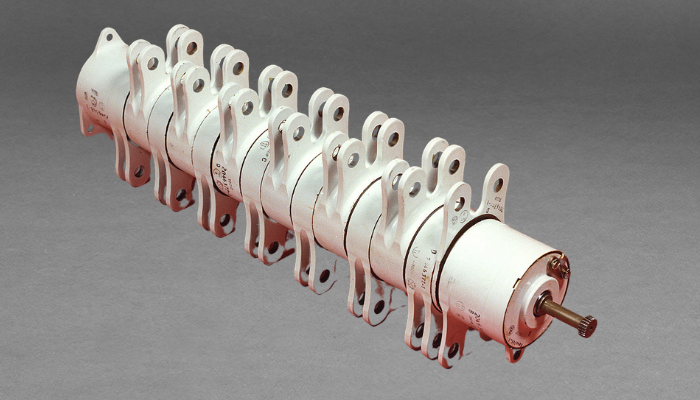

Hinge Line Geared Rotary Actuator

Hinge-line actuators, most commonly found in military leading edge applications use compound differential gearing to provide high-torque low-speed power transmission connecting the flap surface to the spar.