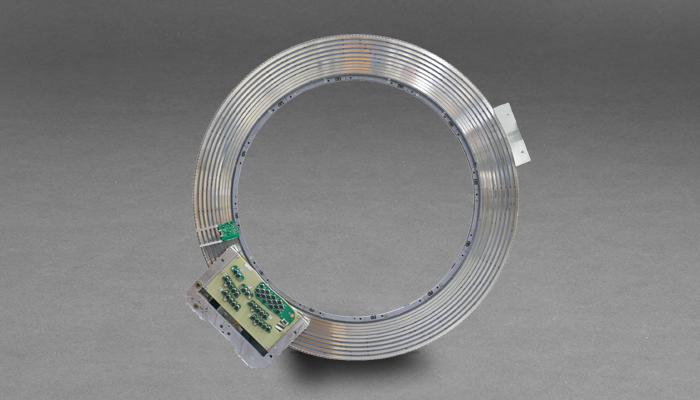

Large Diameter Slip Rings

Fiber Optic Rotary Joint (FORJ)

Large bore optical rotary joints for high speed optical communications with aggregate data rates exceeding 40 Gb/s. This patented technology also has the capability to transfer multiple data signals per optical channel.

- Integrated directly into slip ring or can stand alone

- Inherent EMI immunity

- Multiple electronics options (single channel, multi-channel, FPGA)

- Significant system health diagnostics

- Bidirectional channel support

To learn more, view the optical rotary joints data sheet.

Non-Contacting Data Link (NCDL)

Large bore non-contacting data link for high speed data communications with aggregate data rates exceeding 5 Gb/s.

- Integrate directly into slip ring or can stand alone

- Bidirectional channel support

- Requires less footprint than FORJ option

- Modules packaged within footprint of slip ring

To learn more, view the non-contacting data link data sheet.

| Part Number | Type | ID* | OD* | High Power Qty | Mid Power Qty | Signal Qty | High Power Voltage VAC |

High Power Current (cont.) |

Speed rpm |

| CT6455 |

Drum | 31.952 | 35.044 | 4 | 2 | 8 | 480 | 100 A | 120 |

| CT6536 |

FORJ ONLY | 39.624 | 43.040 | - | - | - | - | - | 300 |

| CT6764 |

Drum | 37.400 | 39.984 | 4 | 2 | 0 | 480 | 100 A | 120 |

| CT6970 |

Platter | 44.291 | 59.916 | 3 | 2 | 6 | 600 | 100 A | 180 |

| CT7013 |

Platter | 38.590 | 56.194 | 4 | 2 | 4 | 400 | 100 A | 180 |

| CT7093 |

Platter | 42.520 | 54.100 | 3 | 2 | 4 | 500 | 100 A | 180 |

| CT7138 |

Platter | 42.047 | 54.094 | 5 | 0 | 4 | 400 | 100 A | 120 |

| CT7311 |

Platter | 39.622 | 54.818 | 4 | 2 | 4 | 380 | 100 A | 180 |

*OD, ID dimension does not include brush block, fiber optic hardware, or non-contacting data link mounting dimension

• All designs are RoHS compliant

• Design to customer specifications

Note: Slip ring designs within these general specifications may be for either military or commercial applications. Slip rings specifically designed for military applications may require licensing for export. Contact factory for export classification.