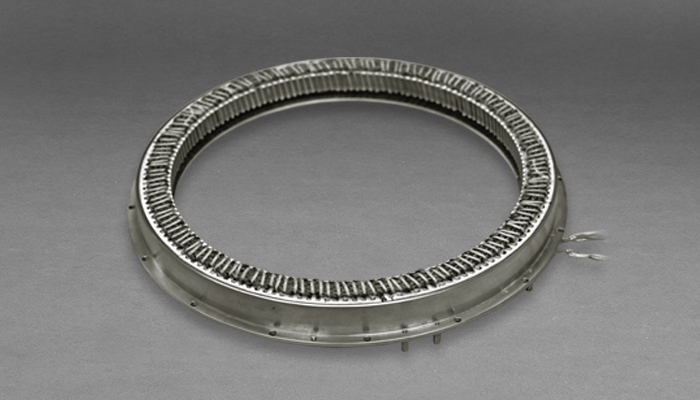

Direct Drive Brush Frameless Torque Motors

Jump To:

Overview

Models

Resources

FEATURES

- Double insulated high temp magnet wire minimizes leakage current, promotes superior insulation

- Molded brush block assembly features interchangeable brush blocks, optimizing brush position on commutator. Brush contour is done on automatic tooling rather than “run-in” individually.

- Brushes mechanically fastened to brush spring in addition to soldering assures brush alignment during soldering operation plus proper mechanical and electrical bond between brush spring and brush.

- Stable high temp encapsulation material minimizes movement or working of windings under large temperature variations. This high temp material will not crack under temperature variations, and eliminates voids, exposed windings and humidity traps.

- Special magnetic material alloy allows higher torque per unit of volume, higher torque to inertia ratio.

- Plated magnet assemblies resist environmental extremes and require no special handling

- Rare earth magnets typical

- High torque and low speed

- High torque to inertia ratio

- Low speed with high accuracy

- Compact

- Large axial holes through armature for easy application to shafts and bosses

TYPICAL APPLICATIONS

- Speed and rotation control systems

- Gimbals for FLIR and inertial navigation systems

- Stabilized gun and fire control systems for combat vehicles

- Fire control radars for land and ship board defense

- Cockpit instrumentation for military and commercial aircraft

- Missle seeker and fin actuator systems

- Space and vacuum instruments, actuation systems and momentum wheels

Frameless Torque Motor Product Listing

| D-1125-B-1 > | D-1125-F-10-T > | D-1125-N-1 > | D-1125-P-10 > | D-1125-P-7 / K044 > | D-1375-F-2ANS > | D-1500-C-3 > | |

| D-1500-E-6 / K012 > | D-1500-Y-1 > | D-1500-Z-1 > | D-1938-R-1AN > | D-2000-D-1NS > | D-2780-B-1AEN > | D-2813-G-1HT > | D-2910-B-1ENS > |

| D-2910-G-1ENS > | D-3000-F-1T > | D-3000-F-3T > | D-3029-A-2EN > | D-3180-C-2A > | D-3180-C-2AE > | D-3180-G-2AE > | D-3180-P-1ES > |

| D-3375-A-1 > | D-3375-A-2 > | D-4500-B-1AS > | D-4610-B-1AS > | D-5125-C-3 > | D-5600-A-1ES > | D-7200-A-1ES > | D-7200-B-1ES > |

| D-7200-C-1ES > | D-8630-C-1 > | D-9000-A-1ES > | D-9000-B-1ES > | D-10020-C-1ANS > | |||

The list above represents only a small sampling of the total range manufactured. Consult factory for additional designs.